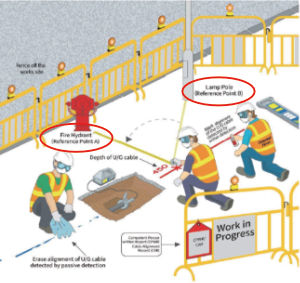

Editor's Notes

Thanks to your continued support, Electricity News has come to its 33rd issue. We have much to offer in this issue, which will be introduced by the charming electrician and the smart store owner, the two male leads appearing in recent TV commercials of the Electrical and Mechanical Services Department (EMSD). The feature article covers the proper completion of the Work Completion Certificate. As to the news-in-brief column, it features reminder for Electricity (Registration) (Amednment) Regulation 2020 and information about the web-based Continuing Professional Development (CPD) training platform, Code of Practice for the Electricity (Wiring) Regulations – new version coming out soon, safety tips for using chargers and power supply units, sharing of insights by Outstanding REWs and Outstanding RECs 2019 and common problems in the preparation of the Competent Person Written Report. And what's more, the Electrical Safety Quiz column challenges you to puzzle the answers out, in the hope of adding fun to your reading and enhancing your knowledge about electrical safety.

Feature Article

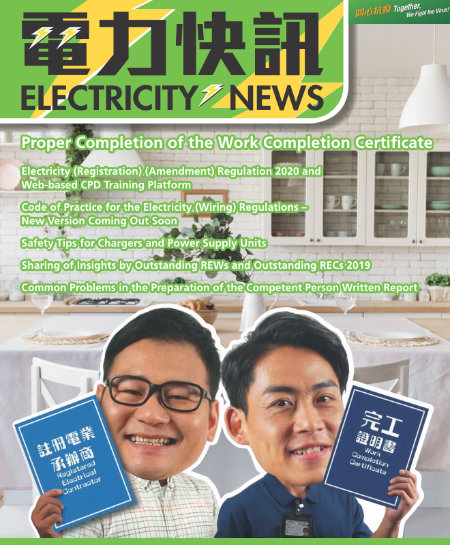

Feature Article - Proper Completion of the Work Completion Certificate

According to the Electricity (Wiring) Regulations, a fixed electrical installation shall, after completion of repair, alteration or addition, and before it is energised for use, be inspected, tested and issued with a Work Completion Certificate (Form WR1) by the responsible REW to confirm that the technical and safety requirements of the relevant Regulations have been met. The REW should also submit the duly signed Work Completion Certificate for endorsement by the REC that employs him. The REC should properly keep the certificate for a period of at least five years.

The EMSD has been actively promoting the importance of the Work Completion Certificate to the trade and owners of fixed electrical installations (including building owners, incorporated owners and property management companies) and emphasising that the issuance of Work Completion Certificate is a statutory requirement. Regardless of whether the issuance of the certificate is included in the works contract, the REW and the REC must inspect, test and issue a Work Completion Certificate after the completion of electrical works and before the fixed electrical installation is energised for use.

Moreover, personnel of the EMSD have found missing or incorrect information on the Work Completion Certificates from time to time during review of the certificates in vetting the generating facility registration applications. The relevant REWs/RECs were then required to clarify or update the information. The common errors, correct ways to complete the Work Completion Certificate and tips are shown below for reference (Please refer to the specimen of a completed Work Completion Certificate appended to the following pictures).

1. Date of the form

| Key date of inspection (1A) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| 1. Missing information |

Fill in the inspection date correctly. |

| 2. Incorrect information |

- The date should not be later than the signature date of the REW (1B).

- The date should not be earlier than the signature date in Part 1 of the form.

- The date should be within one month before the signature date of the REW (1B).

- The date should be later than all the signature dates on Form WR1(A).

|

| Signature dates of the REW (1B) and the REC (1C) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| 1. Missing information |

Fill in the signature date correctly. |

| 2. Date (1C) is earlier than (1A) or (1B), or date (1B) is earlier than (1A) |

- The correct order of dates should be (1A), (1B) and (1C).

- Dates (1B) and (1C) should be within one month from the key inspection date (1A).

|

2. Selection of checkbox/signature

| Whether Form WR1(A) (2A) is appended |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| 1. Missing information |

Select the appropriate checkbox. |

| 2. Incorrect selection |

If Form WR1(A) is not appended, select the upper checkbox. Otherwise, select the lower checkbox. Do not select both checkboxes. |

| Signature of the REW (2B) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| 1. Missing signature |

Signature is required. |

| 2. Photocopy of signature |

Original signature is required. |

| 3. Signature of REW different from the sample signature |

The original signature by the REW must be identical to the sample signature shown in the licence application / renewal application. |

| Signature of the REC (2C) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| 1. Missing signature |

Signature is required. |

| 2. Photocopy of signature |

Original signature is required. |

| 3. Signed by a person not authorised by the REC |

The original signature must be signed by the person authorised by the REC. It must be identical to the sample signature registered at the EMSD and signed with company seal (if applicable). |

3. Address of the fixed electrical installation

| Address of the fixed electrical installation (3A) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| 1. Missing information, incorrect information, incomplete information (e.g. street name or street number missing), etc. |

- Provide accurate information including the street name, street number, floor and flat number of the installation.

- Detailed address should be provided if the building has two street numbers (i.e. located at the junction of two streets).

|

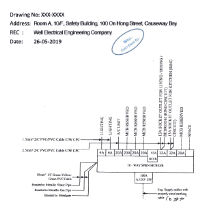

| 2. Address of installation shown on the form inconsistent with the information shown in the schematic wiring diagram |

Ensure that the address of installation shown on the form is correct and consistent with the information shown in the schematic wiring diagram. |

4. Information of the owner of the fixed electrical installation

| Name/organisation/address of the owner of the fixed electrical installation (4A) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| Missing information, incorrect information, incomplete information (e.g. mistakenly filled in the name/address of the REC) |

- Fill in the correct information.

- Owners of installation include the incorporated owners of the building, individual owner, company, etc.

|

| Contact telephone number of the owner of the fixed electrical installation (4B) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| Mistakenly filled in the contact telephone number of the REC |

Fill in the contact telephone number of the owner of the fixed electrical installation. |

5. Information of the fixed electrical installation

| Description of the inspected part of the fixed electrical installation (5) |

|---|

| Common Errors |

Correct ways to complete the Work Completion Certificate and tips |

| Schematic wiring diagram not appended |

Append the schematic wiring diagram. |

News-in-brief

News-in-brief 1 - Electricity (Registration) (Amendment) Regulation 2020 and Web-based CPD Training Platform

According to the Electricity (Registration) (Amendment) Regulation 2020, application for registration or renewal of registration as an electrical contractor or electrical worker received during the concession period from 1 October 2020 to 30 September 2021 (both dates inclusive), the fees are reduced with details as below:

- For the application of registered electrical contractor received during the concession period – the application fee is $570 instead of the original specified fee $855; and

- For the application of registered electrical worker received during the concession period – the application fee is $315 instead of the original specified fee $475.

For the registrations which take effect before and will expire during the concession period, those registered electrical contractor or registered electrical worker will enjoy the waiver if they apply to renew their registrations during the concession period.

Refund will be considered by EMSD for those registrations of electrical contractor or electrical worker which take effect before the concession period (or the application for renewal of registration just submitted before the concession period), are valid for more than one year, and with an expiry date falling beyond the above concession period. Those registered electrical contractors or registered electrical workers could apply for refund through the E&M Trade App from 1 November 2020 to 31 January 2021 (both dates inclusive). Upon eligible application for refund received, EMSD will refund the relevant fee already paid on a pro-rata basis by reference to the concession period. Details are released on EMSD web page and E&M Trade App. You are welcome to download the E&M Trade App by scanning the QR codes right beside.

Refund will be considered by EMSD for those registrations of electrical contractor or electrical worker which take effect before the concession period (or the application for renewal of registration just submitted before the concession period), are valid for more than one year, and with an expiry date falling beyond the above concession period. Those registered electrical contractors or registered electrical workers could apply for refund through the E&M Trade App from 1 November 2020 to 31 January 2021 (both dates inclusive). Upon eligible application for refund received, EMSD will refund the relevant fee already paid on a pro-rata basis by reference to the concession period. Details are released on EMSD web page and E&M Trade App. You are welcome to download the E&M Trade App by scanning the QR codes right beside.

Furthermore, in order to minimise the risk of spreading COVID-19 in the community, the CPD training for REWs at the Registration and Permit Office of the EMSD has been temporarily suspended since 29 January 2020. To facilitate REWs to complete CPD training to fulfil the renewal registration requirements, the EMSD has established a web-based CPD training platform as a temporary training measure. REWs can access the web-based CPD training platform via the below link or QR code right beside.

Furthermore, in order to minimise the risk of spreading COVID-19 in the community, the CPD training for REWs at the Registration and Permit Office of the EMSD has been temporarily suspended since 29 January 2020. To facilitate REWs to complete CPD training to fulfil the renewal registration requirements, the EMSD has established a web-based CPD training platform as a temporary training measure. REWs can access the web-based CPD training platform via the below link or QR code right beside.

Please click here or scan the QR code above to access the CPD training platform.

News-in-brief

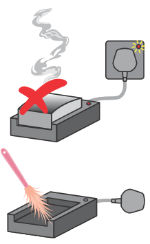

News-in-brief 3 - Safety Tips for Chargers and Power Supply Units

The Electrical Products (Safety) Regulation stipulates that household electrical products supplied in Hong Kong, including chargers and power supply units, should be issued with "certificate of safety compliance" to proof that the products are in compliance with relevant international safety standards or other equivalent safety standards.

Points to note when buying chargers and power supply units

- Do not buy unbranded chargers / power supply units (including chargers / power supply units that come with the electrical products) or those without manufacturer markings and relevant information (e.g. rated voltage, frequency, input power, manufacturer's name and product model).

- Remain vigilant against counterfeit chargers / power supply units. Consider shopping at reputable stores or authorised dealers of relevant brands.

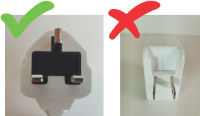

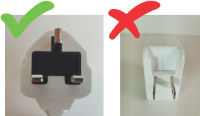

Only buy chargers / power supply units with three-pin plugs suitable to be used in Hong Kong (i.e. plugs that comply with safety standard BS1363 or BS546).

Only buy chargers / power supply units with three-pin plugs suitable to be used in Hong Kong (i.e. plugs that comply with safety standard BS1363 or BS546).- When buying chargers / power supply units, make sure that there are certificates of safety compliance. The suppliers are responsible to confirm the certificates of safety compliance have been issued for the electrical products before procurement. Members of the public may contact the suppliers for enquiries.

- Make sure that the chargers / power supply units are suitable for the electrical products to be connected. Select chargers / power supply units with appropriate power rating to match with the required current, so as to prevent safety hazards due to overload.

Points to note when using chargers and power supply units

Read the manual before using the chargers / power supply units to understand how to use them correctly.

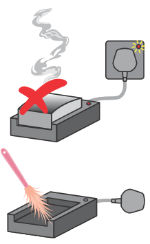

Read the manual before using the chargers / power supply units to understand how to use them correctly. Do not use the chargers / power supply units for a prolonged period of time, so as to prevent accidents due to overheating.

Do not use the chargers / power supply units for a prolonged period of time, so as to prevent accidents due to overheating.- When using the chargers / power supply units, place them within sight. Do not connect them to a power supply for a prolonged period of time. Unplug them or disconnect the power supply after use.

- Since heating will occur when using the chargers / power supply units, use them in a well-ventilated place. They should not be used in environments with high temperature or strong sunlight, or where humidity is high (e.g. bathroom, kitchen, etc.).

- If the chargers / power supply units are found to be damaged, too hot or making abnormal noise, smell or vibration, stop using them immediately and unplug them.

Points to note when maintaining chargers and power supply units

- Place the chargers / power supply units carefully to avoid tangling or damage of the cables.

- In general, chargers / power supply units are not waterproof. Do not wet them.

- Keep the chargers / power supply units clean to avoid accumulation of dust, which will affect their normal operation.

- Do not alter or dismantle the enclosures of the chargers / power supply units, or attempt to repair them by oneself.

For enquiries on the safety of electrical products, please call the Government hotline 1823 or e-mail to info@emsd.gov.hk.

News-in-brief

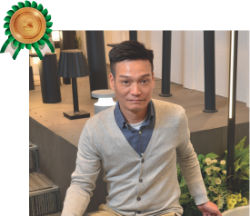

News-in-brief 4 - Sharing of Insights by Outstanding REWs and Outstanding RECs 2019

Outstanding REWs

NG Tsz-kwan

NG Tsz-kwan

Lik Kai Engineering Company Limited

Gold Prize: Simple and Useful Inductive Gadgets Offer Great Protection before Works

Gold Prize: Simple and Useful Inductive Gadgets Offer Great Protection before Works

Electricity leakage may occur if there are damaged cables or faulty electrical equipment near the works area when carrying out electrical work. The condition above false ceiling is even more complicated. Mr NG Tsz-kwan proposed to tie voltage testers onto an "extendable selfie stick" prior to commencement of works, which enables electrical workers to check whether there is electricity leakage near the ceiling grid using the extendable stick at ground level. This can prevent accidents to workers caused by inadvertent touching of the live false ceiling.

YIP Wai-hung

YIP Wai-hung

Lik Kai Engineering Company Limited

Silver Prize: Learn about the Risk of Electric Shock with the Growing Popularity of Solar Panels

Silver Prize: Learn about the Risk of Electric Shock with the Growing Popularity of Solar Panels

In recent years, photovoltaic (PV) modules (solar panels) have been installed on the rooftops of many buildings to convert solar energy into electrical energy through PV effect for use. Nevertheless, cables may be live upon connection of the solar panel to the power grid, and thus there will be a risk of electric shock. In this regard, Mr YIP Wai-hung proposed to install an indicator light or display meter at the output end of the solar panel to identify whether power is being supplied by the solar system. At the same time, a "Warning-Dual Supply" label and a solar power "Warning" label shall be posted on the system for identification so as to avoid the risk of electric shock.

LUI Tin-lung

LUI Tin-lung

Zodiac Lighting Limited

Bronze Prize: Clever Tactic for Varied Outdoor Electricity Applications Ensures Peace of Mind

Bronze Prize: Clever Tactic for Varied Outdoor Electricity Applications Ensures Peace of Mind

Apart from lighting purpose, lights can also embellish the environment. However, cables with a voltage of 220V are still used to supply electricity to the outdoor lighting of many housing estates, commercial buildings, parks, swimming pools and shopping malls, posing a risk of electric shock if water seepage occurs. Mr LUI Tin-lung suggested that power transformers be installed for outdoor lighting and cables with an extra-low voltage of 12V or 24V be used for wiring, thereby ensuring the safety of users and electrical workers.

Outstanding RECs

FUNG Ki-wai, SO King-hong,

FUNG Ki-wai, SO King-hong,

CHAU Yiu-fong

Majestic Engineering Company Limited

Gold Prize: Care about Site Environment, Create a Safe Workplace

Gold Prize: Care about Site Environment, Create a Safe Workplace

Workers at site are responsible for different areas of work. Mr SO King-hong, Mr FUNG Ki-wai and Mr CHAU Yiu-fong of Majestic Engineering Company Limited believed that a temporary four-pole residual current device (RCD) can be installed in the distribution board to replace the traditional main power switch before the inspection of fire service installations and delivery upon completion of works so that the circuit can be cut off swiftly when electricity leakage occurs. This helps reduce the risk of electric shock to workers by accident. Moreover, the company also proposed to replace the current design of a single distribution board cover with a "dual-door distribution board", which can prevent accidents caused by removing the distribution board cover.

CHOY Yuk-ming, TSANG Chi-hin

CHOY Yuk-ming, TSANG Chi-hin

REC Engineering Company Limited

Silver Prize: Application of Modular Integrated Construction Brings Enhanced Economic and Safety Benefits

Silver Prize: Application of Modular Integrated Construction Brings Enhanced Economic and Safety Benefits

Modular integrated construction (MiC) has been actively promoted by the trade in recent years. Mr TSANG Chi-hin and Mr CHOY Yuk-ming of REC Engineering Company Limited considered that design for manufacture and assembly (DfMA) can also be adopted by the electrical and mechanical trade to save the time for on-site construction and assembly. If the trunking of each floor's meter room is pre-assembled, electrical workers can, upon delivery of the trunking to the site, install it directly and complete such processes as cable installation and fixing of meter boards, which can save a lot of manpower and reduce the risk of accidents at site. Besides, self-made simple and small tools are used to help with the testing of in-room electrical appliances and measure the earth fault loop impedance of high-level lampholders, which can effectively improve work efficiency.

NG Man-kei, LEUNG Ching-cheong,

NG Man-kei, LEUNG Ching-cheong,

WONG Wai-leung

Lik Kai Engineering Company Limited

Bronze Prize: Residual Current Devices Offer Safety at Low Cost

Bronze Prize: Residual Current Devices Offer Safety at Low Cost

There are many workers on a works site and they are responsible for different areas of work. Some non-electrical workers may inadvertently touch a circuit under installation and cause danger. To prevent accidents, Ms NG Man-kei, Mr LEUNG Ching-cheong and Mr WONG Wai-leung of Lik Kai Engineering Company Limited proposed a temporary replacement of the main power switch with a four-pole RCD in the distribution board during the transition period before completion of works, with a view to providing workers with better protection.

The EMSD has produced two short videos to share with the electrical trade insights of the winners for trade members' reference so that they can learn about how the winners promote and implement a work safety culture at work.

News-in-brief

News-in-brief 5 - Common Problems in the Preparation of the Competent Person Written Report

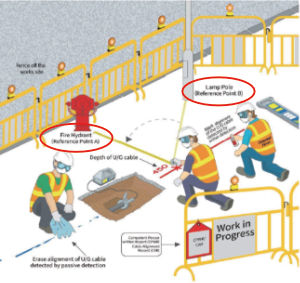

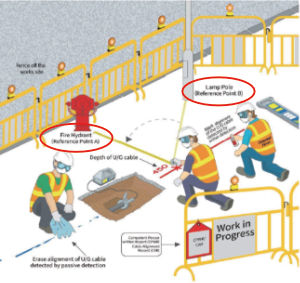

Figure 1

Figure 1

Figure 2

Figure 2

According to the requirements of the Code of Practice on Working near Electricity Supply Lines (CoP), upon completion of active cable detection, the competent person shall prepare a Competent Person Written Report (Written Report) for subsequent submission to the working party appointing him/her and clearly mark the cable alignment and depth on site so as to reduce the risk of electrical accidents or electricity supply interruptions. Since the quality of work and the conduct of competent persons have significant impact on electrical safety of the general public and power supply, common problems in the preparation of the Written Report are listed below for reference and improvement by competent persons:

- the number and voltage of underground (U/G) cables detected are not reported;

- a detailed cable layout plan clearly specifying the alignment ascertained for each U/G cable based on common reference points (e.g. lamp pole, traffic light post, or hydrant, etc. (see Figure 1 for details)) and any cable sections in shallow depth is not provided;

- photos clearly showing the toroidal active detection and site markings for cable alignment and depth are not provided;

- only one cable alignment is used to represent a group of ascertained U/G cables on the layout plan; and

- the distance between the detection points exceeds the limit of three metres.

To facilitate the preparation of the Written Report by competent persons, a sample of the Written Report has been included in Appendix 5 of the CoP (2018 Edition) for reference and use by relevant persons. Competent persons shall be arranged to explain to the frontline staff at the works site the contents of the Written Report upon its completion. The Written Report should also be posted on the barrier or railing at the works site for reference by site personnel.

Readers' Feedback and Update

We look forward to receiving your valuable feedback for continuous improvement so that the contents of Electricity News and the services of the EMSD can better meet your needs. Please complete the form and return it to the Electricity Legislation Division of the EMSD by post, fax or e-mail (contact details at the bottom of this page) on or before 21 February 2021. Thank you.

Contact Information

Address: Electricity Legislation Division, EMSD, 3 Kai Shing Street, Kowloon, Hong Kong

Tel: 1823

Fax: 2895 4929

Email: info@emsd.gov.hk

[PDF format (5.16MB)]

[PDF format (5.16MB)]

Refund will be considered by EMSD for those registrations of electrical contractor or electrical worker which take effect before the concession period (or the application for renewal of registration just submitted before the concession period), are valid for more than one year, and with an expiry date falling beyond the above concession period. Those registered electrical contractors or registered electrical workers could apply for refund through the E&M Trade App from 1 November 2020 to 31 January 2021 (both dates inclusive). Upon eligible application for refund received, EMSD will refund the relevant fee already paid on a pro-rata basis by reference to the concession period. Details are released on EMSD web page and E&M Trade App. You are welcome to download the E&M Trade App by scanning the QR codes right beside.

Refund will be considered by EMSD for those registrations of electrical contractor or electrical worker which take effect before the concession period (or the application for renewal of registration just submitted before the concession period), are valid for more than one year, and with an expiry date falling beyond the above concession period. Those registered electrical contractors or registered electrical workers could apply for refund through the E&M Trade App from 1 November 2020 to 31 January 2021 (both dates inclusive). Upon eligible application for refund received, EMSD will refund the relevant fee already paid on a pro-rata basis by reference to the concession period. Details are released on EMSD web page and E&M Trade App. You are welcome to download the E&M Trade App by scanning the QR codes right beside. Furthermore, in order to minimise the risk of spreading COVID-19 in the community, the CPD training for REWs at the Registration and Permit Office of the EMSD has been temporarily suspended since 29 January 2020. To facilitate REWs to complete CPD training to fulfil the renewal registration requirements, the EMSD has established a web-based CPD training platform as a temporary training measure. REWs can access the web-based CPD training platform via the below link or QR code right beside.

Furthermore, in order to minimise the risk of spreading COVID-19 in the community, the CPD training for REWs at the Registration and Permit Office of the EMSD has been temporarily suspended since 29 January 2020. To facilitate REWs to complete CPD training to fulfil the renewal registration requirements, the EMSD has established a web-based CPD training platform as a temporary training measure. REWs can access the web-based CPD training platform via the below link or QR code right beside.

Only buy chargers / power supply units with three-pin plugs suitable to be used in Hong Kong (i.e. plugs that comply with safety standard BS1363 or BS546).

Only buy chargers / power supply units with three-pin plugs suitable to be used in Hong Kong (i.e. plugs that comply with safety standard BS1363 or BS546). Read the manual before using the chargers / power supply units to understand how to use them correctly.

Read the manual before using the chargers / power supply units to understand how to use them correctly. Do not use the chargers / power supply units for a prolonged period of time, so as to prevent accidents due to overheating.

Do not use the chargers / power supply units for a prolonged period of time, so as to prevent accidents due to overheating.

NG Tsz-kwan

NG Tsz-kwan Gold Prize: Simple and Useful Inductive Gadgets Offer Great Protection before Works

Gold Prize: Simple and Useful Inductive Gadgets Offer Great Protection before Works YIP Wai-hung

YIP Wai-hung Silver Prize: Learn about the Risk of Electric Shock with the Growing Popularity of Solar Panels

Silver Prize: Learn about the Risk of Electric Shock with the Growing Popularity of Solar Panels LUI Tin-lung

LUI Tin-lung Bronze Prize: Clever Tactic for Varied Outdoor Electricity Applications Ensures Peace of Mind

Bronze Prize: Clever Tactic for Varied Outdoor Electricity Applications Ensures Peace of Mind FUNG Ki-wai, SO King-hong,

FUNG Ki-wai, SO King-hong, CHOY Yuk-ming, TSANG Chi-hin

CHOY Yuk-ming, TSANG Chi-hin NG Man-kei, LEUNG Ching-cheong,

NG Man-kei, LEUNG Ching-cheong, Watch Now

Watch Now Figure 1

Figure 1