APPLIANCES AND EQUIPMENT

Variable Speed Drives in Air-conditioning Systems (VSD)

What is Variable Speed Drives (VSD)?

Induction motors that typically used for compressors and fans in air conditioning systems are sized to handle maximum load under worst case conditions and then leaving them to run at full power. They are basically fixed-speed motors. Their speed is determined by the constant frequency of the power supply (typically 50 or 60 Hz).

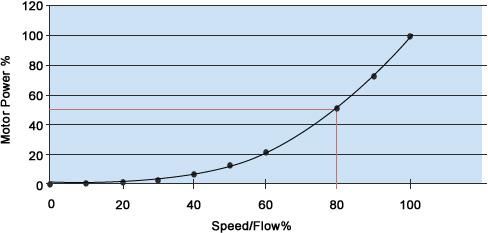

Variable speed drives (VSD) or frequency inverters are solid-state devices and save energy whenever electric motors run at less than full power. VSD is actually a frequency converter in which 50Hz or 60Hz ac input voltage is first rectified into dc which is then converted back into variable-frequency ac voltage. It must be noted that the power demand of motor varies with the cube of the motor speed, i.e. power is proportional to (speed)3.

This means that a reduction of speed by 20% will result in reduction of power consumption by nearly a half, i.e. 50% saving. Since most HVAC equipment seldom runs at full power, significant energy savings can be made with these variable speed drives.

Motor Energy Saving with VSD

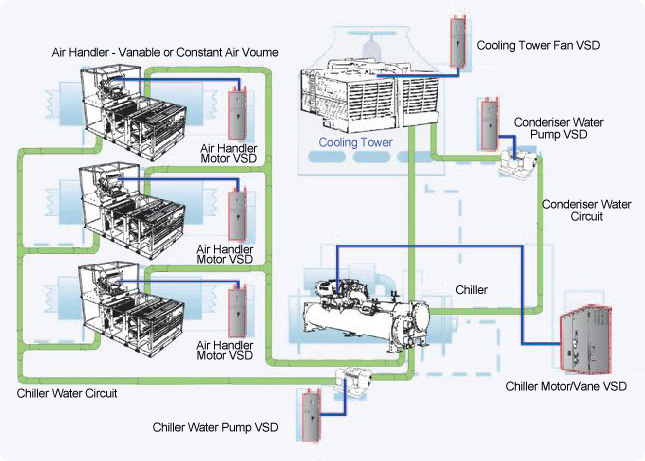

Variable speed drives in air-conditioning systems

The motors on chillers, pumps, cooling towers and fans account for a significant portion of the energy consumption in HVAC system. The use of retrofit variable speed drives (VSD) is one of the most effective technologies applied in recent years. The VSD can be added on to conventional equipment or can be part of the factory-supplied equipment.

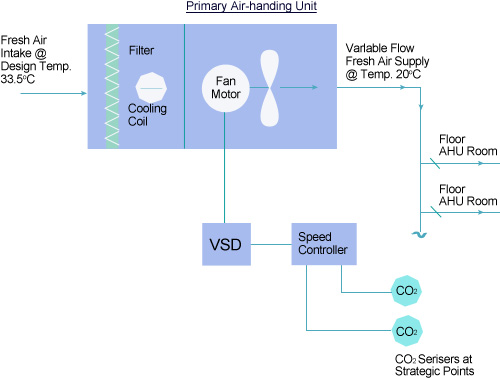

- VSD for PAU (Primary Air-handing Unit)

Conventional Primary Air Handling Units (PAUs) usually pre-treat outdoor air at a constant air volume (i.e. CAV). The PAUs supply air to different areas in the building at a constant air flow rate of full load condition, disregard the actual demand. This will waste energy because the PAUs operate at part load instead of full load in most of the time.

Demand control on PAUs using carbon dioxide (CO2) provides unique opportunity to resolve the problem of how to reduce energy costs while optimizing indoor air quality.

CO2 control is best applied to spaces with variable or intermittent occupancy.

Typical Arrangement of variable flow PAU using VSD & CO2 sensors

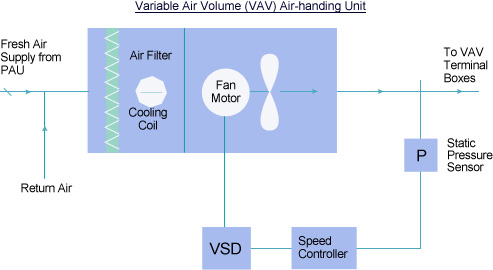

- VSD for VAV System

Variable Air Volume (VAV) systems typically bring conditioned air from PAU and returned air from the air-conditioned space into Air Handling Units (AHU). The air is delivered to each zone through ductworks and individual VAV terminal boxes where temperature sensor is located. Set point temperature is maintained by closing or opening of VAV box. When setpoint temperature is reached, VAV box will be modulated to a close position and consequently the pressure in the ductwork is rose. In this way, VSD can be utilized to decrease the speed of the AHU fan after receiving the pressure level signals from the static pressure sensor in the air duct to provide the flow and pressure required by the system.

Typical Arrangement of VAV AHU using VSD & Pressure Sensors

- VSD for Chilled Water Circuit

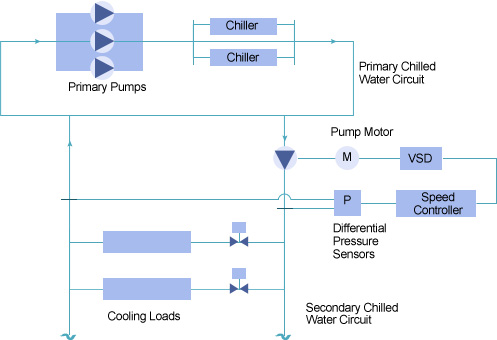

In chilled water system, the primary loop consists of primary pump sized to circulate the chilled water through the chiller and the rest of the primary piping loop. The secondary chiller water loop, which consists of secondary pump, is a variable flow system. Chilled water is circulated by the secondary pump through the control valves and cooling loads connected to the circuit. However, most of the control valves in the circuit are not fully open because of part load in most of the time. Therefore, the chilled water flow in the secondary water loop can be regulated by VSD to handle the chilled water required by the cooling load, thus to save energy.

Variable Chilled Water Flow System using VSD

Energy Efficient HVAC Equipment & Systems

Application example – VSD installations at the EMSD Headquarters