DIGITALISATION ENHANCEMENT: PROMOTING THE APPLICATION OF THE BIM-AM SYSTEM IN THE INDUSTRY

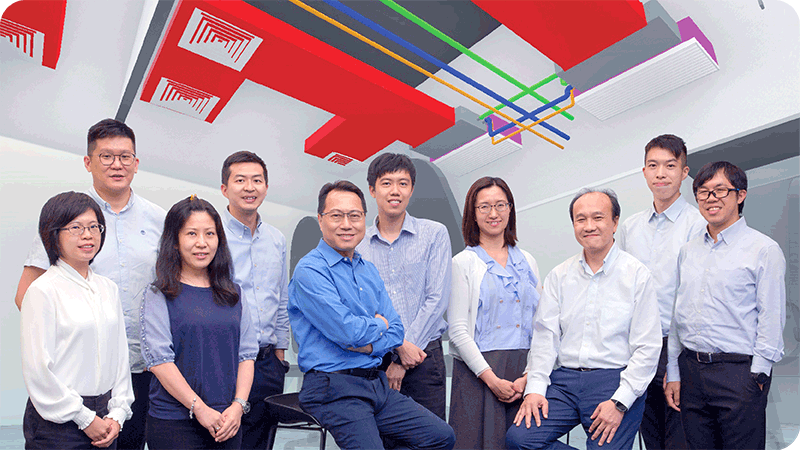

Mr Chan Hor-yin, Steve, a senior engineer (3rd left, front row) and his team

have been responsible for overseeing the development of the BIM-AM system and

departmental Common Data Environment, as well as adopting IoT technologies to

realise digital twins, in order to promote smart city development.

Since 2014, the EMSD has been promoting the application of Building Information

Modelling – Asset Management (BIM-AM), and the Building Information Modelling

Sub-division was established in 2018. "In the construction industry, BIM has gained

wide recognition in the international arena due to its notable value in design and

construction stages. Foreseeing that BIM will become a game changer in the future,

the EMSD began to explore the application of BIM within the service life of

buildings nine years ago," Mr Chan Hor-yin, Steve, a senior engineer of the

Digitalisation and Technology Division recalled.

Mr Chan and his professional team developed the first BIM-AM system prototype, and using the EMSD Headquarters as a pilot, successfully integrated BIM-AM together with wireless and wired real-time system solutions. The team secured a patent in 2016 and published the first BIM-AM Standards and Guidelines in 2017. The third version of the standards and guidelines, together with new handover and acceptance guidelines, was published last year for internal and the trade's reference.

As Internet of Things (IoT) technologies advanced, the BIM team integrated wireless IoT sensors with the BIM-AM system, and constructed the Government-Wide IoT Network after trials in 2019, enabling near real-time monitoring of the E&M systems within the BIM-AM system. They also fostered smart city development in close collaboration with other government departments. "The BIM-AM system, combined with a mobile application, can now display comprehensive E&M equipment data, including real-time data, which assists in remote monitoring and fault diagnosis," explained Mr Chan, who also expressed the hope for adopting artificial intelligence technology to realise digital twins and thereby achieving the goal of predictive maintenance through analysis of real-time data.

With strong support from various divisions and client departments in the past two years, the BIM team has successfully constructed BIM models for over 90 existing government venues. The first BIM-AM application competition was also organised last year, and received overwhelming responses. "Most of the submissions were of high quality, which demonstrated a good understanding of BIM-AM. The team's persistent efforts and internal training over the years havefinally paid off, which was profoundly moving," Mr Chan said.

The team has also been promoting the application of BIM-AM locally and internationally through sharing sessions and conferences, and started to assist contractors and consultants in offering BIM courses five years ago. "As a BIM-AM pioneer in Hong Kong, we have to work harder to improve the system, showcase various applications and uphold established standards, so as to drive ahead the development of digitalisation in Hong Kong," Mr Chan added.

Mr Chan and his professional team developed the first BIM-AM system prototype, and using the EMSD Headquarters as a pilot, successfully integrated BIM-AM together with wireless and wired real-time system solutions. The team secured a patent in 2016 and published the first BIM-AM Standards and Guidelines in 2017. The third version of the standards and guidelines, together with new handover and acceptance guidelines, was published last year for internal and the trade's reference.

As Internet of Things (IoT) technologies advanced, the BIM team integrated wireless IoT sensors with the BIM-AM system, and constructed the Government-Wide IoT Network after trials in 2019, enabling near real-time monitoring of the E&M systems within the BIM-AM system. They also fostered smart city development in close collaboration with other government departments. "The BIM-AM system, combined with a mobile application, can now display comprehensive E&M equipment data, including real-time data, which assists in remote monitoring and fault diagnosis," explained Mr Chan, who also expressed the hope for adopting artificial intelligence technology to realise digital twins and thereby achieving the goal of predictive maintenance through analysis of real-time data.

With strong support from various divisions and client departments in the past two years, the BIM team has successfully constructed BIM models for over 90 existing government venues. The first BIM-AM application competition was also organised last year, and received overwhelming responses. "Most of the submissions were of high quality, which demonstrated a good understanding of BIM-AM. The team's persistent efforts and internal training over the years havefinally paid off, which was profoundly moving," Mr Chan said.

The team has also been promoting the application of BIM-AM locally and internationally through sharing sessions and conferences, and started to assist contractors and consultants in offering BIM courses five years ago. "As a BIM-AM pioneer in Hong Kong, we have to work harder to improve the system, showcase various applications and uphold established standards, so as to drive ahead the development of digitalisation in Hong Kong," Mr Chan added.

EXPLORATION OF GREEN POTENTIAL: ENCOURAGING THE PUBLIC TO WIDELY ADOPT RENEWABLE ENERGY

Renewable energy is inexhaustible and environmentally friendly. To promote its

use, the EMSD has developed the Integrated Self-sustained Renewable Energy

Explorer (iSEE), which accurately assesses the renewable energy power generation

potential and return of the premises of public and private organisations and

individual building owners intended to install renewable energy systems; while

utilising cutting-edge technologies such as big data, digital twin and

artificial intelligence (AI) to collect and analyse renewable energy system

data, and providing organisations and owners who have installed renewable energy

systems with a one-stop platform to check the real-time condition of their

systems, thereby helping them improve their power generation efficiency. Ms

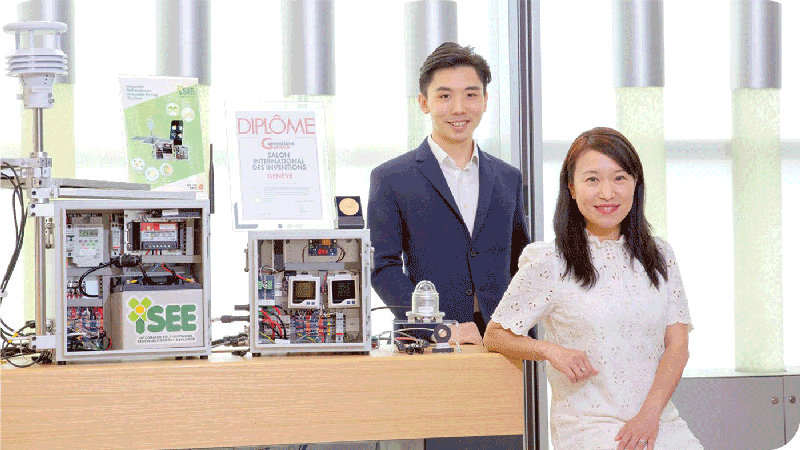

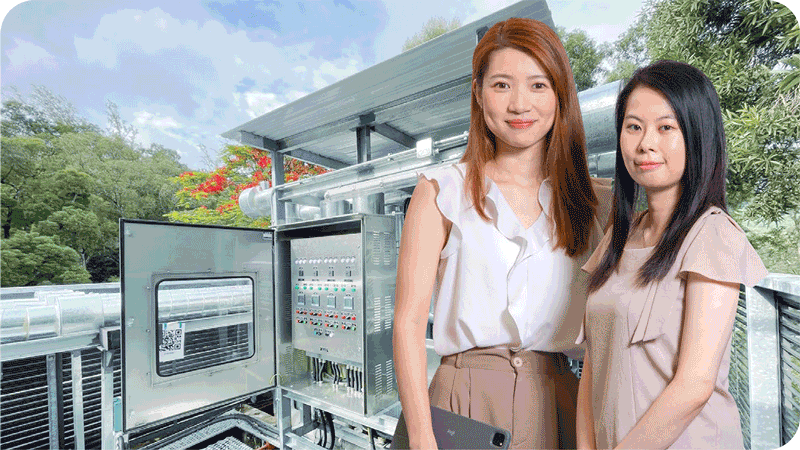

Cheung Man-chit, Jovian, a senior engineer, and Mr Li Chun-yin, an engineer, of

the Energy Efficiency Office, were in charge of the project. They hoped that the

iSEE would be widely adopted and help promote green economy and advance towards

carbon neutrality.

The iSEE comprises two modules, one of which collects a variety of weather

information, such as sunlight, temperature, humidity, wind speed, wind direction and

air pressure at the place of installation, and instantly assesses the energy

generation potential and return, thus strengthening the confidence of organisations

and owners in installing renewable energy systems. The other module can be installed

on existing renewable energy systems. Once the installation is completed, the

back-end system of the iSEE will collect and use the power generation data of the

renewable energy system concerned to build a digital twin, and perform big data

analysis on the power generation system using AI technology. The iSEE is also

equipped with a mobile application, enabling organisations and owners who have

installed renewable energy systems to monitor their systems remotely and receive

information such as real-time fault notifications, recommendations for predictive

maintenance and system optimisation, etc.

Adopting a portable design, the iSEE can be quickly installed at locations without power supply or on existing renewable energy systems. It is also equipped with solar panels and batteries for self-sufficient power supply.

Outlying islands, the countryside and remote areas, as well as the top of footbridges and building rooftops, are suitable locations for installing renewable energy systems. Organisations and owners intended to install renewable energy systems can easily install the iSEE at the above locations and, based on the data analysis performed by the device on the on-site weather data collected, ascertain the optimal locations and orientations for installing renewable energy systems, so as to achieve the highest power generation efficiency.

As for organisations and owners who have installed renewable energy systems, as soon as the iSEE is installed, they can immediately grasp the power generation condition of their systems, gauge the system performance and monitor the impact of weather on the systems for early prediction of maintenance needs, in order to increase the power generated. They will also receive notifications regarding special weather conditions for preparations in advance. The iSEE has been trialled at two local schools. The schools and the maintenance contractors concerned responded that the device had been effective in giving them a clear picture of the operational status of their renewable energy systems.

As society pays increasing attention to environmental, social and governance-related matters, the introduction of the iSEE will help organisations of various scales carry out more effective planning of renewable energy power generation facilities and achieve the best efficiency and highest return. Ms Cheung said the EMSD held two patents for the iSEE and was planning to collaborate with universities and start-ups to commercialise the iSEE, so as to encourage more public and private organisations and companies to install renewable energy systems.

"The Government has been committed to promoting the use of renewable energy, with a view to achieving the carbon neutrality target. The iSEE provides members of the public with a platform for analysing the performance of renewable energy systems and sharing real-time data collected. I hope the iSEE will be widely adopted in Hong Kong so as to expedite the advancement towards the vision of zero-carbon emissions," Ms Cheung said.

The iSEE won a gold medal at the 48th International Exhibition of Inventions of Geneva. Mr Li was heartened by the achievement. "This award brings glory to Hong Kong, giving me and my team a sense of accomplishment. I hope this invention can stimulate innovation, investment and development in renewable energy, promote green economy and contribute to achieving carbon neutrality," he said.

Adopting a portable design, the iSEE can be quickly installed at locations without power supply or on existing renewable energy systems. It is also equipped with solar panels and batteries for self-sufficient power supply.

Outlying islands, the countryside and remote areas, as well as the top of footbridges and building rooftops, are suitable locations for installing renewable energy systems. Organisations and owners intended to install renewable energy systems can easily install the iSEE at the above locations and, based on the data analysis performed by the device on the on-site weather data collected, ascertain the optimal locations and orientations for installing renewable energy systems, so as to achieve the highest power generation efficiency.

As for organisations and owners who have installed renewable energy systems, as soon as the iSEE is installed, they can immediately grasp the power generation condition of their systems, gauge the system performance and monitor the impact of weather on the systems for early prediction of maintenance needs, in order to increase the power generated. They will also receive notifications regarding special weather conditions for preparations in advance. The iSEE has been trialled at two local schools. The schools and the maintenance contractors concerned responded that the device had been effective in giving them a clear picture of the operational status of their renewable energy systems.

As society pays increasing attention to environmental, social and governance-related matters, the introduction of the iSEE will help organisations of various scales carry out more effective planning of renewable energy power generation facilities and achieve the best efficiency and highest return. Ms Cheung said the EMSD held two patents for the iSEE and was planning to collaborate with universities and start-ups to commercialise the iSEE, so as to encourage more public and private organisations and companies to install renewable energy systems.

"The Government has been committed to promoting the use of renewable energy, with a view to achieving the carbon neutrality target. The iSEE provides members of the public with a platform for analysing the performance of renewable energy systems and sharing real-time data collected. I hope the iSEE will be widely adopted in Hong Kong so as to expedite the advancement towards the vision of zero-carbon emissions," Ms Cheung said.

The iSEE won a gold medal at the 48th International Exhibition of Inventions of Geneva. Mr Li was heartened by the achievement. "This award brings glory to Hong Kong, giving me and my team a sense of accomplishment. I hope this invention can stimulate innovation, investment and development in renewable energy, promote green economy and contribute to achieving carbon neutrality," he said.

BUILDING SOLAR HARVEST MAP FOR ENHANCING EDUCATION AND MONITORING

Through the Solar Harvest scheme, the EMSD installed solar energy generation

systems for about 600 eligible schools and welfare non-governmental

organisations (NGOs) and assisted them to join the Feed-in Tariff (FiT) scheme.

Furthermore, the EMSD has collaborated with the Environment and Ecology Bureau

and the Education Bureau in compiling educational kits, which can be used in

conjunction with the solar energy generation systems in the schools, to arouse

students' interest in learning science, as well as enhancing their knowledge

about renewable energy and awareness of combating climate change. Recently, the

EMSD has specially established a platform called the Solar Harvest Map,

delivering additional multi-functions regarding the solar energy generation

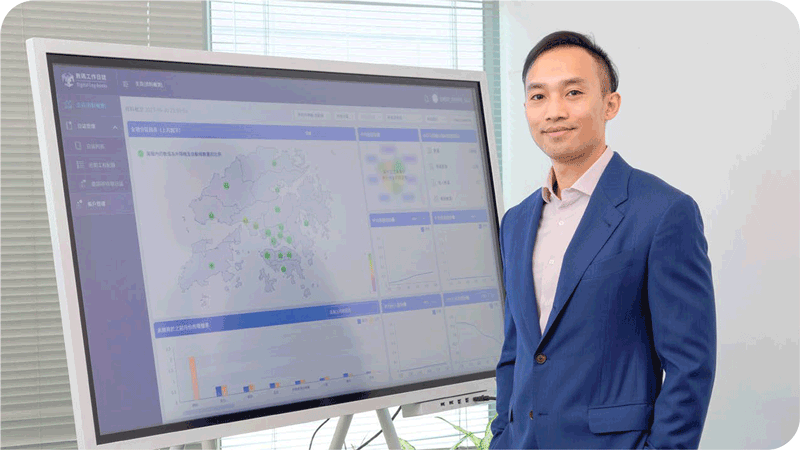

systems to the schools and NGOs joining the Solar Harvest scheme. Mr Cheung

Yiu-yeung, Kelvin, an engineer of the Energy Efficiency Office, took the lead in

establishing this platform.

Connecting hundreds of solar energy generation systems in those schools and NGOs

joining the Solar Harvest scheme, the Solar Harvest Map provides users with a

real-time intelligent monitoring platform to grasp the performance of their solar

power generation facilities and facilitate predictive maintenance. Meanwhile, the

Solar Harvest Map also serves as an interactive learning platform that enhances the

environmental awareness of younger generations.

"The schools can display a television showing information on the platform in a conspicuous position for students to check the performance of the solar energy generation facilities in their schools at any time. Teachers can also interact with students through the platform, such as organising in-school activities and competitions to share relevant information; and utilising the real-time data for discussion with students on topics such as the impact of sunlight on solar energy generation," Mr Cheung explained.

Developing the Solar Harvest Map is valuable for the Solar Harvest scheme as it consolidates the data of all solar energy generation systems under the Solar Harvest scheme. Not only can the users employ the data to monitor their solar energy generation systems, the EMSD can also grasp the renewable energy contributions of all schools and NGOs under the whole scheme in real time.

Talking about the development of the Solar Harvest Map, Mr Cheung said, "In the future, we will integrate an artificial intelligence-based alert function into the platform to notify the schools to arrange preventive maintenance in case of any abnormalities detected in the solar energy generation systems, so that the schools can receive the FiT income continually. We will also add more functions to promote interactive learning, which will enable young people to understand early the contribution of renewable energy to power generation and realisation of zero-carbon living, and thereby forging ahead together towards the target of carbon neutrality."

"The schools can display a television showing information on the platform in a conspicuous position for students to check the performance of the solar energy generation facilities in their schools at any time. Teachers can also interact with students through the platform, such as organising in-school activities and competitions to share relevant information; and utilising the real-time data for discussion with students on topics such as the impact of sunlight on solar energy generation," Mr Cheung explained.

Developing the Solar Harvest Map is valuable for the Solar Harvest scheme as it consolidates the data of all solar energy generation systems under the Solar Harvest scheme. Not only can the users employ the data to monitor their solar energy generation systems, the EMSD can also grasp the renewable energy contributions of all schools and NGOs under the whole scheme in real time.

Talking about the development of the Solar Harvest Map, Mr Cheung said, "In the future, we will integrate an artificial intelligence-based alert function into the platform to notify the schools to arrange preventive maintenance in case of any abnormalities detected in the solar energy generation systems, so that the schools can receive the FiT income continually. We will also add more functions to promote interactive learning, which will enable young people to understand early the contribution of renewable energy to power generation and realisation of zero-carbon living, and thereby forging ahead together towards the target of carbon neutrality."

LAUNCH OF DIGITAL LOG-BOOKS MARKS A NEW MILESTONE FOR COLLABORATION

To enhance the management and safety of lifts and escalators, the EMSD led the

research and development and launched the Digital Log-books for Lifts and

Escalators (Digital Log-books). Mr Mentor Cheung, an engineer of the General

Legislation Division, is in charge of the relevant coordination work. He worked

closely with various stakeholders in developing the digital system that benefits

the trade and the public.

Traditionally, the EMSD has been keeping important information and data, including

technical information, maintenance plans, maintenance records, fault history records

and incident records, in paper form. However, paper records have certain

limitations, such as difficulties in ascertaining information accuracy and

inconvenience in record keeping. In view of this, the EMSD has developed the Digital

Log-books to serve as a centralised electronic platform for central storage and

analysis of records previously scattered in the management offices of individual

buildings. This not only provides more comprehensive information to owners and

managers of lifts and escalators (collectively referred to as responsible persons)

and the trade, but also allows the EMSD to regulate lift and escalator safety more

effectively, thereby enhancing the service standards of the trade as a

whole.

The primary task of Mr Cheung was to liaise with and bring together all stakeholders, including the lifts, escalators and property management trades, professional organisations and public utility companies, to jointly explore the development of a system that benefits all parties. Then, he and the Digitalisation and Technology Division of the EMSD worked with a blockchain start-up to pool efforts for the development of the Digital Log-books.

With the concerted effort of various parties, the development of the system was completed within a relatively short period of time and the system was officially launched in November 2022 for use by the trade. Within just a few months after the launch, the number of users reached over 7000, involving more than 20000 lifts and escalators, which accounted for more than 20% of all the lifts and escalators in Hong Kong. Mr Cheung was heartened by such enthusiastic response from the stakeholders.

The success of the project is a result of the joint effort of Mr Cheung and his team. Adopting a multi-pronged approach, they produced tutorial videos, organised seminars, set up hotlines and even proactively reached out to potential users to encourage responsible persons and the trade to migrate from paper records to the Digital Log-books so as to enjoy the benefits brought about by I&T as soon as possible.

The Digital Log-books won the Gold Prize in the category of Excellence in Team Collaboration (Regulatory Service) in the Civil Service Outstanding Service Award Scheme 2022, affirming the hard work and outstanding achievements of the development team while underscoring the spirit of collaboration among the stakeholders.

"In the early stage of developing the Digital Log-books, we had concern that the system might be too unconventional and ahead of its time, and worried about its acceptance by the trade. Nevertheless, after we introduced the design concept of the Digital Log-books to the trade, we received wide support from the working groups which comprised trade practitioners, contractors and representatives of responsible persons. During the trial run of the system at the later stage, different parties of the trade also collaborated fully with us. The introduction of the Digital Log-books won unanimous approval from users. Their positive feedback has been very encouraging to us, and I am chuffed about what has been achieved," Mr Cheung concluded.

The primary task of Mr Cheung was to liaise with and bring together all stakeholders, including the lifts, escalators and property management trades, professional organisations and public utility companies, to jointly explore the development of a system that benefits all parties. Then, he and the Digitalisation and Technology Division of the EMSD worked with a blockchain start-up to pool efforts for the development of the Digital Log-books.

With the concerted effort of various parties, the development of the system was completed within a relatively short period of time and the system was officially launched in November 2022 for use by the trade. Within just a few months after the launch, the number of users reached over 7000, involving more than 20000 lifts and escalators, which accounted for more than 20% of all the lifts and escalators in Hong Kong. Mr Cheung was heartened by such enthusiastic response from the stakeholders.

The success of the project is a result of the joint effort of Mr Cheung and his team. Adopting a multi-pronged approach, they produced tutorial videos, organised seminars, set up hotlines and even proactively reached out to potential users to encourage responsible persons and the trade to migrate from paper records to the Digital Log-books so as to enjoy the benefits brought about by I&T as soon as possible.

The Digital Log-books won the Gold Prize in the category of Excellence in Team Collaboration (Regulatory Service) in the Civil Service Outstanding Service Award Scheme 2022, affirming the hard work and outstanding achievements of the development team while underscoring the spirit of collaboration among the stakeholders.

"In the early stage of developing the Digital Log-books, we had concern that the system might be too unconventional and ahead of its time, and worried about its acceptance by the trade. Nevertheless, after we introduced the design concept of the Digital Log-books to the trade, we received wide support from the working groups which comprised trade practitioners, contractors and representatives of responsible persons. During the trial run of the system at the later stage, different parties of the trade also collaborated fully with us. The introduction of the Digital Log-books won unanimous approval from users. Their positive feedback has been very encouraging to us, and I am chuffed about what has been achieved," Mr Cheung concluded.

PERFECTING SMART DRAINAGE SYSTEM FOR FLOOD PREVENTION

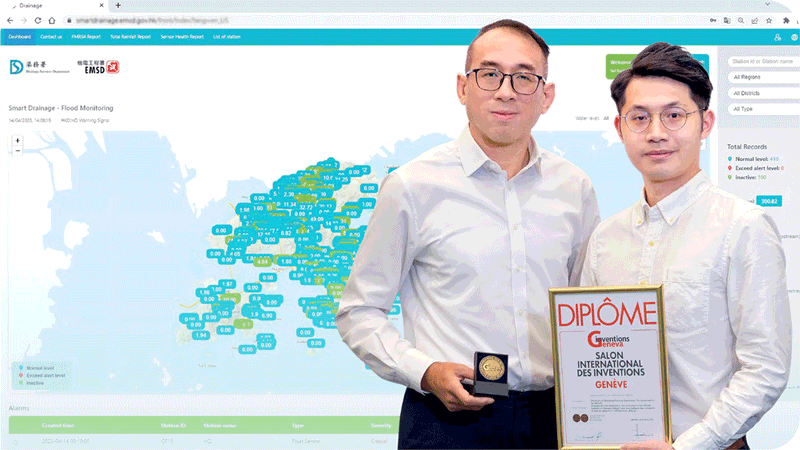

The Smart Drainage – Flood Monitoring System has gradually matured since its

development in 2019, thanks to the breakthroughs made by Mr Lam Kwan-yin, Henry,

an engineer (right), and Mr Wang Chun-kit, Johnny, an electronics inspector

(left).

To address the substantial risks posed by climate change to the environment and

society, the EMSD and the Drainage Services Department (DSD) collaborated to develop

the Smart Drainage – Flood Monitoring System. This system, which began operation

during the typhoon season, continuously tracks real-time variations in water levels

and flows across rivers, seas, and channels, facilitating early detection and

prediction of potential flooding risks.

“Nearly 140 monitoring points have been installed so far," said Mr Lam Kwan-yin, Henry, the engineer of the Security and Vehicle Services Division (SVSD) in charge of project co-ordination. “Since 2019, we have implemented a new system utilising low-power wide-area network Internet of Things sensors (LPWAN IoT sensors) and Long Range cameras (LoRaCam) of the Government, enabling real-time cross-platform flood monitoring and alarm within the existing drainage system. Moreover, integrating data from the Hong Kong Observatory, we have more precise analysis."

"The new system offers greater cost-effectiveness, costing only 1/20 of the traditional gauging stations," said Mr Wang Chun-kit, Johnny, an electronics inspector of the SVSD with extensive frontline experience. "The new system operates on batteries, eliminating the need for wiring, and requires only about a week for installation. In addition, to optimise the battery life, in consultation with the DSD, we adjust the measurement frequency in response to weather changes, in order to reduce energy consumption."

The EMSD was recently entrusted with the crucial task of installing the flood monitoring system at the high risk precarious water-logging spot of Ap Tsai Hang, Lau Fau Shan prior to the rainy season. Mr Wang said, "The team efficiently completed the task within a week, and the monitoring point demonstrated its efficacy during a subsequent red rainstorm, underscoring the importance of this system. We also began battery life monitoring to predict when the battery needs replacement and maintenance, which facilitates advance planning for material procurement and maintenance schedules."

The Smart Drainage System for Flood Monitoring using LPWAN IoT sensors and LoRaCam received a bronze award at the International Exhibition of Inventions of Geneva 2023. "Winning the award is certainly encouraging, but being able to protect public safety and property is what truly makes our efforts worthwhile," said Mr Lam. "I hope to continuously refine the system and see its application expand to more locations, so that even more people will benefit in the future."

“Nearly 140 monitoring points have been installed so far," said Mr Lam Kwan-yin, Henry, the engineer of the Security and Vehicle Services Division (SVSD) in charge of project co-ordination. “Since 2019, we have implemented a new system utilising low-power wide-area network Internet of Things sensors (LPWAN IoT sensors) and Long Range cameras (LoRaCam) of the Government, enabling real-time cross-platform flood monitoring and alarm within the existing drainage system. Moreover, integrating data from the Hong Kong Observatory, we have more precise analysis."

"The new system offers greater cost-effectiveness, costing only 1/20 of the traditional gauging stations," said Mr Wang Chun-kit, Johnny, an electronics inspector of the SVSD with extensive frontline experience. "The new system operates on batteries, eliminating the need for wiring, and requires only about a week for installation. In addition, to optimise the battery life, in consultation with the DSD, we adjust the measurement frequency in response to weather changes, in order to reduce energy consumption."

The EMSD was recently entrusted with the crucial task of installing the flood monitoring system at the high risk precarious water-logging spot of Ap Tsai Hang, Lau Fau Shan prior to the rainy season. Mr Wang said, "The team efficiently completed the task within a week, and the monitoring point demonstrated its efficacy during a subsequent red rainstorm, underscoring the importance of this system. We also began battery life monitoring to predict when the battery needs replacement and maintenance, which facilitates advance planning for material procurement and maintenance schedules."

The Smart Drainage System for Flood Monitoring using LPWAN IoT sensors and LoRaCam received a bronze award at the International Exhibition of Inventions of Geneva 2023. "Winning the award is certainly encouraging, but being able to protect public safety and property is what truly makes our efforts worthwhile," said Mr Lam. "I hope to continuously refine the system and see its application expand to more locations, so that even more people will benefit in the future."

WHOLEHEARTED DEDICATION OF YOUNG ENGINEERS IN THE EMSTF'S FIRST MIMEP PILOT PROJECT

Ms Li Hoi-ching, Chelsea (right) and Ms Wong Tsz-kwan, Chris (left), two young

engineers from the General Engineering Services Division, took forward the

Chiller Plant Replacement project at Tai Lung Veterinary Laboratory with utmost

dedication, exploring tirelessly the ways to implement MiMEP application and

taking care of every aspect meticulously.

The Chiller Plant Replacement project at Tai Lung Veterinary Laboratory was selected

by the EMSTF as the first pilot Multi-trade integrated Mechanical, Electrical and

Plumbing (MiMEP) project. "The MiMEP technology is typically applied in newly built

large-scale buildings. However, in our project, the chillers are located on the

congested rooftop of an existing building, presenting even greater challenges to the

project. Yet in the light of this, the challenges sparked our innovative ideas on

the application of new technological solutions. Our team embarked on transforming

the site and its surrounding environment into a point cloud model by

three-dimensional (3D) laser scanning and drones, and subsequently developed a

Building Information Modelling (BIM) 3D model to simulate the entire construction

process, encompassing delivery, hoisting and module assembly. This comprehensive

simulation provided us with better control over the project progress and site

co-ordination, and also helped mitigate potential risks," Ms Wong Tsz-kwan, Chris,

an engineer of the General Engineering Services Division (GESD) explained.

"Through BIM simulation, we designed eight modules for this replacement project and completed the prefabrication in a local factory. During the assembly process, we applied innovative technologies such as employment of pre-insulated pipes and robotic welding, which not only enhanced precision and efficiency but also curtailed noise, material waste and potential safety issues in crowded environments," Ms Li Hoi-ching, Chelsea, an engineer of the GESD added.

Before construction, the team employed augmented reality technology in conjunction with the BIM model to inspect possible restrictions and challenges that may arise during construction and maintenance in order to develop solutions in advance. "Upon completion of the works, we fully utilised the BIM model for real-time monitoring in the operation and maintenance platforms and further semantic artificial intelligent analytics, in order to optimise the operational efficiency of the chiller plant," Ms Wong said.

Without precedent cases for reference, all steps, including which technologies to adopt, required the team to spend time exploring, discussing and repeatedly experimenting and modifying in order to complete the project. The two engineers said, "The project was executed during the epidemic when material transportation delays were common. Fortunately, the application of MiMEP technology simplified the process and significantly reduced the construction time from about 90 days to 38 days. We hope the success of this project will inspire confidence in the industry to adopt MiMEP technology for future repair, maintenance, alteration and addition works." The project was awarded an Honourable Mention at the Autodesk Hong Kong BIM Awards 2022, which was very encouraging for everyone involved.

"Through BIM simulation, we designed eight modules for this replacement project and completed the prefabrication in a local factory. During the assembly process, we applied innovative technologies such as employment of pre-insulated pipes and robotic welding, which not only enhanced precision and efficiency but also curtailed noise, material waste and potential safety issues in crowded environments," Ms Li Hoi-ching, Chelsea, an engineer of the GESD added.

Before construction, the team employed augmented reality technology in conjunction with the BIM model to inspect possible restrictions and challenges that may arise during construction and maintenance in order to develop solutions in advance. "Upon completion of the works, we fully utilised the BIM model for real-time monitoring in the operation and maintenance platforms and further semantic artificial intelligent analytics, in order to optimise the operational efficiency of the chiller plant," Ms Wong said.

Without precedent cases for reference, all steps, including which technologies to adopt, required the team to spend time exploring, discussing and repeatedly experimenting and modifying in order to complete the project. The two engineers said, "The project was executed during the epidemic when material transportation delays were common. Fortunately, the application of MiMEP technology simplified the process and significantly reduced the construction time from about 90 days to 38 days. We hope the success of this project will inspire confidence in the industry to adopt MiMEP technology for future repair, maintenance, alteration and addition works." The project was awarded an Honourable Mention at the Autodesk Hong Kong BIM Awards 2022, which was very encouraging for everyone involved.

BRAVING THE WIND AND THE BILLOWS FOR THE GAS SAFETY REGULATION OF OFFSHORE LIQUEFIED NATURAL GAS TERMINAL

The offshore liquefied natural gas (LNG) terminal (the terminal) co-constructed

by the two power companies of Hong Kong is located in the waters about 4 km east

of Tau Lo Chau near the Soko Islands. In the past two years, the EMSD team of

engineers responsible for regulating the safety of the terminal's gas

installations often took ferry rides, rain or shine, to conduct on-site

monitoring of critical tests. From the vetting stage onwards, they had been

fully involved in the regulatory and approval work to ensure the safe

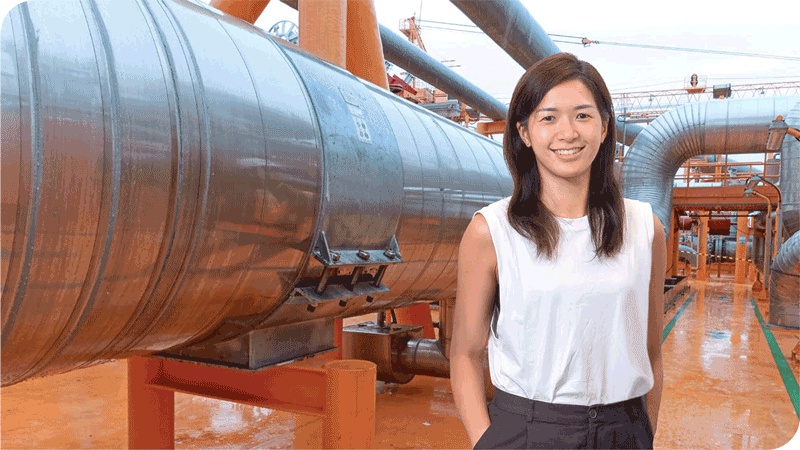

construction and use of gas installations. Ms Li Siu Ying, Rachel, an engineer

of the Gas Standards Office (GasSO), is a key member of the team.

Ms Li joined the team that regulates the safety of the terminal immediately after

assuming her position at the GasSO in August 2022. She has for numerous times

boarded the ferry arranged by the two power companies, braving the wind and the

waves to travel to the terminal with her colleagues and engineering personnel for

on-site monitoring of the critical gas installation tests, including leak tests of

high-pressure natural gas pipelines and emergency shutdown system tests for the

marine loading arms at the terminal. Every time, they went all out, making the most

of their five-hour stay at the terminal to monitor multiple tests related to the

approval work.

The trips to the terminal were seldom smooth sailing. Though weather forecasts could be made reference to in scheduling the journeys, the weather in the open sea was somehow capricious. Ms Li recalled an unforgettable experience, "Once after we set off, the wind picked up to force 5. We were tossed about on the ferry for two hours before arriving at the terminal, but the waves were too high that we could not disembark. We had no choice but to divert to Cheung Chau and wait until the wind subsided to return to Tsim Sha Tsui. The waves were incredibly unforgiving then, rocking the ferry violently. Most of us were rather seasick, and even the highly experienced overseas experts who joined us on that trip were throwing up. Being a weak swimmer, I was scared and held onto a life jacket tightly for dear life."

All the works and gas safety tests for the terminal have been more or less completed, and the terminal is expected to be commissioned in mid-2023 as scheduled. The EMSD is actively developing a remote monitoring system for ongoing monitoring of the alarm system of the gas facilities on the terminal. However, such innovative tools will not negate the need for on-site monitoring of tests and inspections. Even after the terminal commences operation, Ms Li will still need to conduct on-site inspections frequently.

Ms Li will not be deterred by the rough seas in continuing this meaningful mission. She stated, "This terminal not only enhances Hong Kong's long-term energy reliability, but also allows Hong Kong to negotiate better terms for purchasing natural gas in the global market. The terminal is the world's first and largest offshore double-berth steel structure, and an essential infrastructure that supports Hong Kong in moving towards carbon neutrality as well. Being a strong advocate for environmental protection with a deep appreciation for nature, I am honoured to be involved in such a magnificent natural gas infrastructure, through which we can build a more environmental friendly and safer living environment for the public while contributing to Hong Kong's carbon neutrality goal for the good of nature."

The trips to the terminal were seldom smooth sailing. Though weather forecasts could be made reference to in scheduling the journeys, the weather in the open sea was somehow capricious. Ms Li recalled an unforgettable experience, "Once after we set off, the wind picked up to force 5. We were tossed about on the ferry for two hours before arriving at the terminal, but the waves were too high that we could not disembark. We had no choice but to divert to Cheung Chau and wait until the wind subsided to return to Tsim Sha Tsui. The waves were incredibly unforgiving then, rocking the ferry violently. Most of us were rather seasick, and even the highly experienced overseas experts who joined us on that trip were throwing up. Being a weak swimmer, I was scared and held onto a life jacket tightly for dear life."

All the works and gas safety tests for the terminal have been more or less completed, and the terminal is expected to be commissioned in mid-2023 as scheduled. The EMSD is actively developing a remote monitoring system for ongoing monitoring of the alarm system of the gas facilities on the terminal. However, such innovative tools will not negate the need for on-site monitoring of tests and inspections. Even after the terminal commences operation, Ms Li will still need to conduct on-site inspections frequently.

Ms Li will not be deterred by the rough seas in continuing this meaningful mission. She stated, "This terminal not only enhances Hong Kong's long-term energy reliability, but also allows Hong Kong to negotiate better terms for purchasing natural gas in the global market. The terminal is the world's first and largest offshore double-berth steel structure, and an essential infrastructure that supports Hong Kong in moving towards carbon neutrality as well. Being a strong advocate for environmental protection with a deep appreciation for nature, I am honoured to be involved in such a magnificent natural gas infrastructure, through which we can build a more environmental friendly and safer living environment for the public while contributing to Hong Kong's carbon neutrality goal for the good of nature."

SERVING THE COMMUNITY WITH EXPERTISE: PRODUCING FACILITIES FOR GUIDE DOG ROAD-LEADING TRAINING

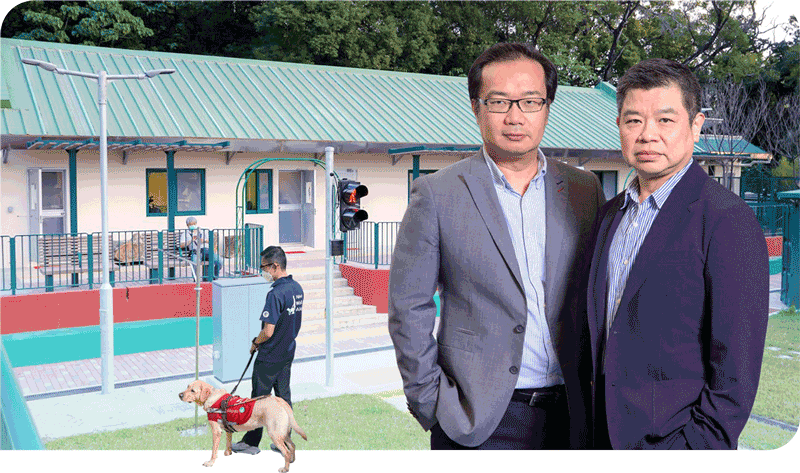

Mr Ng Man-to, an engineer (left) and Mr Mok Wai-po, a regional manager (right)

led a team to install the Pedestrian Crossing Light System for Guide Dog

Training at the Hong Kong Seeing Eye Dog Training School to facilitate local

guide dogs' road-leading training.

In the past, guide dogs mainly received road-leading training on public streets, but

this might pose dangers to other road users and impose limitations on the training

process. To meet these challenges, the team offered the solution of the Pedestrian

Crossing Light System for Guide Dog Training. In addition to ensuring the safety of

both guide dogs and visually impaired people during road-leading training, this

solution also enhanced training flexibility and minimised interruptions from

external factors.

"We used existing traffic lights and customised the design to meet the special needs of the school. This marks the first application of such a device in road-leading training for guide dogs in Hong Kong," said Mr Ng Man-to, an engineer of the Boundary Crossing Facilities and Transport Services Division (BTSD).

The project was a pioneering endeavour without precedent. The team had to comprehensively consider various aspects from design, modification, construction to testing, and propose feasible and user-friendly technical solutions based on the school's environment and guide dog training methods. To suit the users' needs, the system was specifically modified. Moreover, upon modification, it featured adjustable timing of the green light, as well as volume and angle of the speaker, which may be modified in accordance with the training content. The controllers concerned also underwent changes in tuning settings, software updates and wiring modifications, staging stable and reliable performance.

"The school environment is always different from public streets, necessitating some unique modifications. For example, since the device is only used for in-school training, we have reduced the system sensitivity to avoid frequent inspections. Also, as the school is located near residential areas, we have added an independent on/off switch to prevent the sound of the speaker from disturbing residents nearby," added Mr Mok Wai-po, a regional manager of the BTSD.

Officially launched on 8 December 2022, the system has heralded a new era of road-leading training for local guide dogs following its successful completion in mid-October 2022. "We have always aimed to contribute to society with our expertise. Through this project, we have come to realise that the supply of guide dogs in Hong Kong falls short of the demand. Now, with the Pedestrian Crossing Light System for Guide Dog Training, we hope to facilitate guide dogs' road-leading training in the school and expedite the allocation of guide dogs to visually impaired people," Mr Ng said.

"We used existing traffic lights and customised the design to meet the special needs of the school. This marks the first application of such a device in road-leading training for guide dogs in Hong Kong," said Mr Ng Man-to, an engineer of the Boundary Crossing Facilities and Transport Services Division (BTSD).

The project was a pioneering endeavour without precedent. The team had to comprehensively consider various aspects from design, modification, construction to testing, and propose feasible and user-friendly technical solutions based on the school's environment and guide dog training methods. To suit the users' needs, the system was specifically modified. Moreover, upon modification, it featured adjustable timing of the green light, as well as volume and angle of the speaker, which may be modified in accordance with the training content. The controllers concerned also underwent changes in tuning settings, software updates and wiring modifications, staging stable and reliable performance.

"The school environment is always different from public streets, necessitating some unique modifications. For example, since the device is only used for in-school training, we have reduced the system sensitivity to avoid frequent inspections. Also, as the school is located near residential areas, we have added an independent on/off switch to prevent the sound of the speaker from disturbing residents nearby," added Mr Mok Wai-po, a regional manager of the BTSD.

Officially launched on 8 December 2022, the system has heralded a new era of road-leading training for local guide dogs following its successful completion in mid-October 2022. "We have always aimed to contribute to society with our expertise. Through this project, we have come to realise that the supply of guide dogs in Hong Kong falls short of the demand. Now, with the Pedestrian Crossing Light System for Guide Dog Training, we hope to facilitate guide dogs' road-leading training in the school and expedite the allocation of guide dogs to visually impaired people," Mr Ng said.

MINIMISING LAW ENFORCEMENT NEEDS THROUGH PUBLICITY AND EDUCATION ON PREVENTION CULTURE

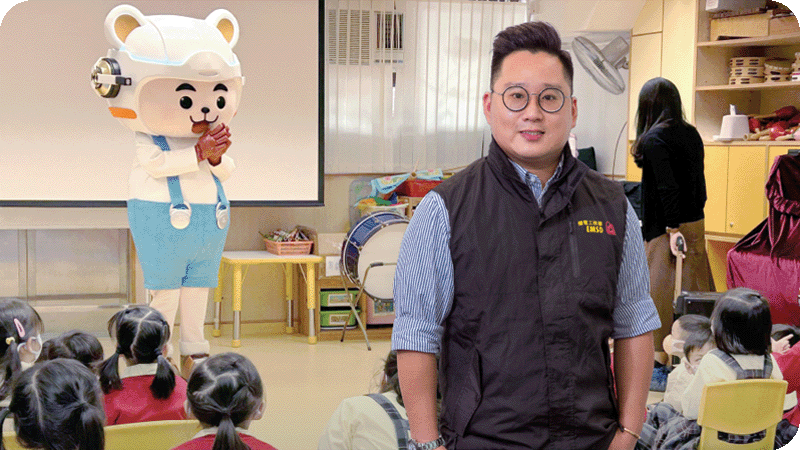

Mr Ng Chui-keung, Nick, an assistant mechanical inspector of the Gas Standards

Office (GasSO) responsible for application approval, law enforcement, publicity

and education, said that of all his work areas, he got the most satisfaction

from publicity and education work, because effective publicity and education

could raise public awareness of gas safety, which would in turn reduce the

chance of gas accidents.

Mr Ng joined the EMSD in 2011 and initially worked in the Health Sector Division,

where he was mainly engaged in technical work such as maintenance, repair and

management of various electrical and mechanical installations in hospitals. In 2020,

he was transferred to the GasSO, and since then he has undertaken regulatory work

such as vetting of registration documents, incident investigation and law

enforcement. He is also responsible for publicity and education, which is exactly

the largest source of his sense of mission and satisfaction. "With proper

prevention, many incidents and law enforcement actions can be avoided," he

said.

The publicity and education work of the EMSD has a diverse target audience, including the general public, children and various ethnic minorities. To effectively reach out to the target groups, the EMSD has adopted a focused strategy. For example, to make promotion and education for children more vivid and interesting, and to leave a lasting impression on them, he and his team produced an educational animation video on gas safety in early 2023.

"In the animation video, we cartoonise everyday objects such as gas cookers and gas water heaters and use bright colours to help convey gas safety messages to children. We broadcast the animation video during a school outreach activity. The students were engrossed in the animation video and enthusiastically participated in the Q&A session that followed. We were pleased to see that after just one class, they had learnt that the EMSD is the gatekeeper of gas safety and that people should use gas appliances bearing a GU mark; and the teachers also gained a deeper understanding of the EMSD's regulatory role in gas safety and relevant legislation. The publicity and education purposes were effectively achieved," he said.

Foreign domestic helpers (FDHs) are also our major targets for disseminating gas safety messages. "The living environment of the FDHs in their hometowns varies from that in Hong Kong. Their understanding of gas safety often differs considerably from the legislative requirements in Hong Kong. As the FDHs are usually users of household gas appliances, it is very important to instil in them gas safety knowledge applicable to the local environment," Mr Ng remarked.

In this light, he and his team produced promotional leaflets in the mother tongues of the FDHs to promote gas safety in simple and straight-forward language, and collaborated with FDH service organisations to distribute the promotional leaflets to FDHs during their activities.

Mr Ng opined that gas safety awareness should be cultivated from an early age. The objectives of the publicity and education work of the EMSD are to instil correct knowledge of gas safety in children and pass on the knowledge from generation to generation. The department also aims to raise the awareness of FDHs regarding gas safety and, through them, spread the relevant messages to other FDHs, their employers and family members.

The publicity and education work of the EMSD has a diverse target audience, including the general public, children and various ethnic minorities. To effectively reach out to the target groups, the EMSD has adopted a focused strategy. For example, to make promotion and education for children more vivid and interesting, and to leave a lasting impression on them, he and his team produced an educational animation video on gas safety in early 2023.

"In the animation video, we cartoonise everyday objects such as gas cookers and gas water heaters and use bright colours to help convey gas safety messages to children. We broadcast the animation video during a school outreach activity. The students were engrossed in the animation video and enthusiastically participated in the Q&A session that followed. We were pleased to see that after just one class, they had learnt that the EMSD is the gatekeeper of gas safety and that people should use gas appliances bearing a GU mark; and the teachers also gained a deeper understanding of the EMSD's regulatory role in gas safety and relevant legislation. The publicity and education purposes were effectively achieved," he said.

Foreign domestic helpers (FDHs) are also our major targets for disseminating gas safety messages. "The living environment of the FDHs in their hometowns varies from that in Hong Kong. Their understanding of gas safety often differs considerably from the legislative requirements in Hong Kong. As the FDHs are usually users of household gas appliances, it is very important to instil in them gas safety knowledge applicable to the local environment," Mr Ng remarked.

In this light, he and his team produced promotional leaflets in the mother tongues of the FDHs to promote gas safety in simple and straight-forward language, and collaborated with FDH service organisations to distribute the promotional leaflets to FDHs during their activities.

Mr Ng opined that gas safety awareness should be cultivated from an early age. The objectives of the publicity and education work of the EMSD are to instil correct knowledge of gas safety in children and pass on the knowledge from generation to generation. The department also aims to raise the awareness of FDHs regarding gas safety and, through them, spread the relevant messages to other FDHs, their employers and family members.

QUICK RESPONSE IN AN ELECTRICAL CRISIS

At around 7:20 pm on 21 June 2022 when the engineers and inspectors of the

Electricity Legislation Division (ELD) were having dinner with their families,

they received the shocking news that the cable bridge of CLP Power Hong Kong

Limited (CLP) in Yuen Long had caught fire. The team mobilised immediately to

join the emergency response action.

The ELD team swung into action in different directions. Some rushed to the scene to

evaluate the situation and supervise the power resumption and emergency repair works

of CLP while preparing for a complex incident investigation. Some headed to the

Emergency Monitoring and Support Centre (EMSC) at the Central Government Offices to

take part in the coordination and emergency response. Others compiled an avalanche

of information to prepare preliminary incident report, reference materials and the

line-to-take. The whole process demonstrated ELD's emergency preparedness and

response for major incident.

Mr Wong Tsz-chung, Jack, ELD's Senior Electrical and Mechanical Engineer/Nuclear and Utility Safety, recalled: "In addition to ELD, other EMSD strategic business units also rallied to maintain normal operation of emergency and basic services, including urgent repair of traffic lights, deployment of back-up emergency power generators for use by hospitals affected by the power outage, and repairing and maintaining the basic operations of the facilities of government departments and public service organisations. Even after the power was restored, the EMSD continued to stay alert and monitor the situation until the power supply was stable."

Mr. Lam Tin-sheung, Timmy, ELD's Electrical and Mechanical Engineer/Nuclear and Utility Safety, added: "In the power restoration process, we maintained close communication with CLP to obtain the latest information on power supply situation and how long it would take to restore power. However, under the dire circumstances, CLP was hard put to provide an exact time table. As the regulator of power companies, we were under a lot of pressure for not getting the full picture. Even when CLP was restoring power by stages, we stayed at EMSC overnight to continue our support and coordination to ensure the 170000-plus households affected by this incident had their power supply restored. We only left EMSC when it was deactivated at 11:40 am the following day."

Meanwhile, Mr. Leung Yiu Ming, who was former ELD's Senior Electrical Inspector /Nuclear and Utility Safety, set off immediately to the incident site with another colleague after receiving the “shocking” news. "On the way, I was mentally running through the things to do for collecting evidence. After we got there and did a preliminary observation, we joined the Fire Services Department (FSD) for the coordination work at the temporary command centre on site. It was like walking into a movie set where the commander was busy assigning tasks to different units. Representing the EMSD, we provided technical advice based on the site condition and electrical safety aspect."

On the day after the incident, ELD's Chief Electrical & Mechanical Engineer Ms. Cheng Pui-man immediately formed a special task force comprising engineers from various subdivisions of ELD, a chief technical officer, and inspectors. The members either have in-depth experience in fire incident investigations or rich knowledge in power supply systems or are very familiar with fire regulations. They dived into the massive load of follow-up work, including conducting immediate inspections of similar cable bridges and their improvement works of fire services installations, monitoring the repair progress of the three sets of damaged 132 kV cables for the full restoration of reliable power supply in the affected areas, and following up on the incident investigation, etc.

The incident investigation was full of challenges. The EMSD joined various departments including the FSD, the Hong Kong Police Force and the Government Laboratory to conduct a joint investigation. ELD's Chief Tech Officer/Consumer Installations Mr Lam Wai-kei was one of the first people to enter the incident bridge to collect evidence. “After burning for three to four hours, the structure of the bridge was unstable. We had to wait for a few days until the bridge was reinforced before we could enter in small groups. After we went in, we could see the cable bridge was seriously damaged by the fire. Our task was to investigate whether the fire was caused by electrical installations. Suspicious spots needed to be checked along the entire cable bridge. First, the suspected fire origin had to be found as much as possible according to the on-site environment, and nearby electrical installation that might caught fire had to be checked, and then the numerous possibilities had to be eliminated one by one.

The on-site investigation was very challenging. Mr Leung Yiu-ming recalled: "It was very hot in Hong Kong at that time. When we entered the bridge, it was like entering a sauna. The area with water inside the bridge was like a steam room while the area outside the bridge in open space was like sun-bathing, with only a small tree for shade to rest. Subsequently, when typhoon signal no. 8 was hoisted on 1 July, we still had to go back to the site to collect samples for the ongoing investigation."

The ensuing investigation took time, but the collapsed cable bridge would have to be demolished soon afterward as it was blocking the drainage channel. This would also remove all the site details. As such, ELD leveraged innovative technology and procured a 360 camera to film the entire condition along the cable bridge to capture all site details into digital records. The footage was very important for the ongoing investigation as the team could revisit the site digitally anytime and even enlarge the high-resolution images to examine any detail.

Mr Ho Kin-yip, Henry, ELD's Electrical and Mechanical Engineer/Nuclear and Utility Safety, searched and procured the appropriate 360 camera, as well as compiled daily updates during the investigation process. "My work began immediate after my colleagues finished the day's investigation and inspections. Daily updates were consolidated within a few hours to facilitate colleagues and the management to keep track with the progress of the investigation and the repair work. The amount of information processed in the follow-up work was massive, with digital data taking up tens of Gb of storage space."

Ms Wong Yee-ching, Stephanie, Electrical and Mechanical Engineer/Nuclear and Utility Safety, was consolidating all information about the incident to prepare responses to enquiries. "Immediately after the incident, a preliminary incident report had to be prepared and written, and enquires from the relevant public and media had to be handled as well. Afterward, I participated in drafting documents related to including relevant information and the line-to-take, etc. to prepare for responses to relevant questions from legislators. At the same time, it was necessary to prepare press releases and consolidate relevant internal as well as inter-departmental documents and information."

To ensure the investigation was impartial to allay public concerns, the EMSD engaged third-party experts to conduct studies and desk-top research and provide recommendations on the improvement measures. CLP also invited experts from different fields to join its investigation. A life-sized simulated model was built for verifying the incident's causes. It was eventually proven that a fluorescent light installed below a cross beam caught fire and ignited the nearest pilot cable below, and then the fire spread to the adjacent high-voltage cables. After the investigation, CLP completed improvement measures, including adding fire prevention and fire-fighting installations, and replacing all low-voltage electrical installations that could cause fire. With our liaison with FSD, WSD, and BD, these measures were implemented to all cable bridges of CLP within a short time.

The incident underscored the importance of prevention. Mr Jack Wong said: "After the incident, we not only supervised CLP in installing fire services installations in similar cable bridges, but also urged CLP to take medium- to long-term measures of conducting risk assessments for relevant power transmission facilities, as well as review its emergency response measures. We planned to conduct a drill in end-2023, simulating a major incident, to enhance the speed of power restoration and improve the flow of reporting and updating. After this incident, we were more convinced that it was important to always ask questions and stay vigilant. Even if a potential hazard seemed highly unlikely to occur, the consequence once occurred was very dire, so we had to be attentive to minimise the possible occurance of incidents. In the future, when we deal with major incidents, we have to put effort on the communication works so that even in the post-incident confusion, all departments and the regulatees communicate well through effective instant communication channels."

Mr Wong Tsz-chung, Jack, ELD's Senior Electrical and Mechanical Engineer/Nuclear and Utility Safety, recalled: "In addition to ELD, other EMSD strategic business units also rallied to maintain normal operation of emergency and basic services, including urgent repair of traffic lights, deployment of back-up emergency power generators for use by hospitals affected by the power outage, and repairing and maintaining the basic operations of the facilities of government departments and public service organisations. Even after the power was restored, the EMSD continued to stay alert and monitor the situation until the power supply was stable."

Mr. Lam Tin-sheung, Timmy, ELD's Electrical and Mechanical Engineer/Nuclear and Utility Safety, added: "In the power restoration process, we maintained close communication with CLP to obtain the latest information on power supply situation and how long it would take to restore power. However, under the dire circumstances, CLP was hard put to provide an exact time table. As the regulator of power companies, we were under a lot of pressure for not getting the full picture. Even when CLP was restoring power by stages, we stayed at EMSC overnight to continue our support and coordination to ensure the 170000-plus households affected by this incident had their power supply restored. We only left EMSC when it was deactivated at 11:40 am the following day."

Meanwhile, Mr. Leung Yiu Ming, who was former ELD's Senior Electrical Inspector /Nuclear and Utility Safety, set off immediately to the incident site with another colleague after receiving the “shocking” news. "On the way, I was mentally running through the things to do for collecting evidence. After we got there and did a preliminary observation, we joined the Fire Services Department (FSD) for the coordination work at the temporary command centre on site. It was like walking into a movie set where the commander was busy assigning tasks to different units. Representing the EMSD, we provided technical advice based on the site condition and electrical safety aspect."

On the day after the incident, ELD's Chief Electrical & Mechanical Engineer Ms. Cheng Pui-man immediately formed a special task force comprising engineers from various subdivisions of ELD, a chief technical officer, and inspectors. The members either have in-depth experience in fire incident investigations or rich knowledge in power supply systems or are very familiar with fire regulations. They dived into the massive load of follow-up work, including conducting immediate inspections of similar cable bridges and their improvement works of fire services installations, monitoring the repair progress of the three sets of damaged 132 kV cables for the full restoration of reliable power supply in the affected areas, and following up on the incident investigation, etc.

The incident investigation was full of challenges. The EMSD joined various departments including the FSD, the Hong Kong Police Force and the Government Laboratory to conduct a joint investigation. ELD's Chief Tech Officer/Consumer Installations Mr Lam Wai-kei was one of the first people to enter the incident bridge to collect evidence. “After burning for three to four hours, the structure of the bridge was unstable. We had to wait for a few days until the bridge was reinforced before we could enter in small groups. After we went in, we could see the cable bridge was seriously damaged by the fire. Our task was to investigate whether the fire was caused by electrical installations. Suspicious spots needed to be checked along the entire cable bridge. First, the suspected fire origin had to be found as much as possible according to the on-site environment, and nearby electrical installation that might caught fire had to be checked, and then the numerous possibilities had to be eliminated one by one.

The on-site investigation was very challenging. Mr Leung Yiu-ming recalled: "It was very hot in Hong Kong at that time. When we entered the bridge, it was like entering a sauna. The area with water inside the bridge was like a steam room while the area outside the bridge in open space was like sun-bathing, with only a small tree for shade to rest. Subsequently, when typhoon signal no. 8 was hoisted on 1 July, we still had to go back to the site to collect samples for the ongoing investigation."

The ensuing investigation took time, but the collapsed cable bridge would have to be demolished soon afterward as it was blocking the drainage channel. This would also remove all the site details. As such, ELD leveraged innovative technology and procured a 360 camera to film the entire condition along the cable bridge to capture all site details into digital records. The footage was very important for the ongoing investigation as the team could revisit the site digitally anytime and even enlarge the high-resolution images to examine any detail.

Mr Ho Kin-yip, Henry, ELD's Electrical and Mechanical Engineer/Nuclear and Utility Safety, searched and procured the appropriate 360 camera, as well as compiled daily updates during the investigation process. "My work began immediate after my colleagues finished the day's investigation and inspections. Daily updates were consolidated within a few hours to facilitate colleagues and the management to keep track with the progress of the investigation and the repair work. The amount of information processed in the follow-up work was massive, with digital data taking up tens of Gb of storage space."

Ms Wong Yee-ching, Stephanie, Electrical and Mechanical Engineer/Nuclear and Utility Safety, was consolidating all information about the incident to prepare responses to enquiries. "Immediately after the incident, a preliminary incident report had to be prepared and written, and enquires from the relevant public and media had to be handled as well. Afterward, I participated in drafting documents related to including relevant information and the line-to-take, etc. to prepare for responses to relevant questions from legislators. At the same time, it was necessary to prepare press releases and consolidate relevant internal as well as inter-departmental documents and information."

To ensure the investigation was impartial to allay public concerns, the EMSD engaged third-party experts to conduct studies and desk-top research and provide recommendations on the improvement measures. CLP also invited experts from different fields to join its investigation. A life-sized simulated model was built for verifying the incident's causes. It was eventually proven that a fluorescent light installed below a cross beam caught fire and ignited the nearest pilot cable below, and then the fire spread to the adjacent high-voltage cables. After the investigation, CLP completed improvement measures, including adding fire prevention and fire-fighting installations, and replacing all low-voltage electrical installations that could cause fire. With our liaison with FSD, WSD, and BD, these measures were implemented to all cable bridges of CLP within a short time.

The incident underscored the importance of prevention. Mr Jack Wong said: "After the incident, we not only supervised CLP in installing fire services installations in similar cable bridges, but also urged CLP to take medium- to long-term measures of conducting risk assessments for relevant power transmission facilities, as well as review its emergency response measures. We planned to conduct a drill in end-2023, simulating a major incident, to enhance the speed of power restoration and improve the flow of reporting and updating. After this incident, we were more convinced that it was important to always ask questions and stay vigilant. Even if a potential hazard seemed highly unlikely to occur, the consequence once occurred was very dire, so we had to be attentive to minimise the possible occurance of incidents. In the future, when we deal with major incidents, we have to put effort on the communication works so that even in the post-incident confusion, all departments and the regulatees communicate well through effective instant communication channels."

HERITAGE OF EXPERIENCE: MONITORING THE PEAK TRAM UPGRADING FOR OPENING A NEW CHAPTER

Monitoring the upgrading project of the Peak Tram was undoubtedly a precious

opportunity for engineers, particularly as the Peak Tram of Hong Kong is one of

the most distinctive funicular systems in the world. Mr Leung Hing Tung, Gary, a

senior engineer, and Mr Chow Ka Kin, an engineer, of the Railways Branch (RB)

are privileged and proud to have been engaged in this historic project.

Commenced in 2018, the upgrading project of the Peak Tram was completed and the

six-generation tram was officially put into service in August 2022. This huge

project involved extensive replacement of the tramcars, haulage system, controls,

signalling system, ropes, track rails and more. At the same time, substantial

expansion and comprehensive renovation works were carried out in the termini in

Central and on the Peak.

"The design of the Hong Kong Peak Tram is quite unique," Mr Leung pointed out. "Similar funicular systems in other countries generally have a consistent gradient for the tracks, and the routes are mostly straight. However, in the case of the Peak Tram of Hong Kong, the track has varying gradients at different sections, and even bends according to the terrain. Moreover, since the rope is elastic itself and its tension changes when the tram runs, its elongation will also vary. Therefore, the dynamic condition of the tram should be taken into consideration in designing the operation system.

Due to the uniqueness of the project, there are few institutions in the world that have relevant expertise. In the course of the project, the RB team maintained communication with experts from Germany through video conferences to ensure perfection in all aspects. The team also applied their experience accumulated from other railway projects to act as the gatekeeper in ensuring safe operations, while acquiring experience in such projects from overseas experts.

"We had regulatory experience with the previous generation of the Peak Tram and knew the distinctive environment in which the Peak Tram operated. These helped us review the system design," Mr Chow said. "For example, based on our experience of the previous generation, we made recommendations to the Peak Tramways Company Limited on modifying the unique waved floor of the new-generation of tramcars. Before the design was finalised, we also conducted on-site testing by installing the new waved floor of an existing tramcar to make sure that passengers could comfortably stand at different gradient sections, thereby mitigating the risk of losing balance. The acceptance was not given to the contractor for manufacturing until we were satisfied with the test results."

In order to share this invaluable engineering experience, the team made a series of short videos at critical stages of the project, documenting important design and test details, including the brake system testing, operating principle of the Peak Tram and operation of various safety components, etc., for internal reference of the team and passing on of experience.

On the day the sixth-generation Peak Tram was launched, Mr Leung, like other Peak Tram fans, could not wait to order tickets, and shared with his family the joy of seeing the new Peak Tram commissioning and his pride in involving in the project. "I rarely told my family about my work, but that day I explained to them on the new Peak Tram its design and the project experience, so that they could better understand my work," Mr Leung said.

After the new generation of Peak Tram is put into operation, the two RB engineers and their team will continue to conduct regular safety inspections on various aspects of the Peak Tram, including the electrical and mechanical systems, power system, tramcars, tracks and ropes, etc. Also, they will partake in the rescue drills jointly organised by the Peak Tramways Company Limited and relevant departments to ensure that the Peak Tram systems always remain in the optimal and safe operating condition, so that everyone can ride with confidence.

"The design of the Hong Kong Peak Tram is quite unique," Mr Leung pointed out. "Similar funicular systems in other countries generally have a consistent gradient for the tracks, and the routes are mostly straight. However, in the case of the Peak Tram of Hong Kong, the track has varying gradients at different sections, and even bends according to the terrain. Moreover, since the rope is elastic itself and its tension changes when the tram runs, its elongation will also vary. Therefore, the dynamic condition of the tram should be taken into consideration in designing the operation system.

Due to the uniqueness of the project, there are few institutions in the world that have relevant expertise. In the course of the project, the RB team maintained communication with experts from Germany through video conferences to ensure perfection in all aspects. The team also applied their experience accumulated from other railway projects to act as the gatekeeper in ensuring safe operations, while acquiring experience in such projects from overseas experts.

"We had regulatory experience with the previous generation of the Peak Tram and knew the distinctive environment in which the Peak Tram operated. These helped us review the system design," Mr Chow said. "For example, based on our experience of the previous generation, we made recommendations to the Peak Tramways Company Limited on modifying the unique waved floor of the new-generation of tramcars. Before the design was finalised, we also conducted on-site testing by installing the new waved floor of an existing tramcar to make sure that passengers could comfortably stand at different gradient sections, thereby mitigating the risk of losing balance. The acceptance was not given to the contractor for manufacturing until we were satisfied with the test results."

In order to share this invaluable engineering experience, the team made a series of short videos at critical stages of the project, documenting important design and test details, including the brake system testing, operating principle of the Peak Tram and operation of various safety components, etc., for internal reference of the team and passing on of experience.

On the day the sixth-generation Peak Tram was launched, Mr Leung, like other Peak Tram fans, could not wait to order tickets, and shared with his family the joy of seeing the new Peak Tram commissioning and his pride in involving in the project. "I rarely told my family about my work, but that day I explained to them on the new Peak Tram its design and the project experience, so that they could better understand my work," Mr Leung said.

After the new generation of Peak Tram is put into operation, the two RB engineers and their team will continue to conduct regular safety inspections on various aspects of the Peak Tram, including the electrical and mechanical systems, power system, tramcars, tracks and ropes, etc. Also, they will partake in the rescue drills jointly organised by the Peak Tramways Company Limited and relevant departments to ensure that the Peak Tram systems always remain in the optimal and safe operating condition, so that everyone can ride with confidence.

RESPONDING TO CHALLENGES WITH ADAPTABILITY AND FLEXIBILITY: FULL SUPPORT TO THE RETURN OF HONG KONG SEVENS

As the Hong Kong Sevens returned to the Hong Kong Stadium, Mr Wong Ka-lun (2nd

right) and the team, led by Mr Chan Ka-ming (2nd left), provided comprehensive

support with strengthened epidemic prevention measures for the tournament.

After a three-year hiatus, the Hong Kong Sevens finally returned to the Hong Kong

Stadium on 4 to 6 November 2022. As the tournament was the first major international

event held in Hong Kong since the epidemic, and considering the substantial number

of participants involved, the Government was concerned about its epidemic prevention

arrangements.

Mr Wong Ka-lun, an electrical inspector of the Municipal Sector Division, and his team are responsible for providing electrical and mechanical support for the tournament. They not only installed E&M equipment for the venue and provided technical support for the live broadcasting system, but also assisted in epidemic prevention. "Due to the epidemic, we had to complete all installation work swiftly and step up various epidemic prevention measures, such as installing numerous air purifiers to ensure adequate fresh air ventilation in the stadium, using disinfection robots for air purification in the suites, measuring on-site air changes, and conducting adjustment, cleaning, inspection and testing for all exhaust, fresh air, and air-conditioning systems in the stadium. Thanks to colleagues' agility and proactive co-operation, we were able to complete the task on schedule," Mr Wong said.

In addition to a large international audience, the tournament had a visit from an unexpected guest, Typhoon Nalgae. Typhoon Signal No. 8 was hoisted several days before the tournament, prompting the team to disassemble the outdoor equipment and relocate them indoors, as well as strengthening the protection of the outdoor temporary power supplies, all within an extremely short period of time. As soon as the typhoon was over, the team immediately restored all equipment to operational status, ensuring the smooth running of the tournament. "We encountered significant challenges under the double blow of the epidemic and the typhoon. Nevertheless, our colleagues rose to the occasion and devoted their utmost efforts to supporting the tournament. Their flexible responses and prompt actions truly embody the 'Hong Kong speed'," Mr Wong shared.

Despite a hectic schedule, the team found time to share their expertise. Specifically, training courses were organised for young colleagues to familiarise them with the operation and maintenance of the audio-visual equipment, live broadcasting system and scoreboard of the stadium. Mr Wong said that the sharing of hands-on experience allowed young colleagues to better understand the preparation work for major events, equipping them with valuable knowledge for their future work.