Pursuant to the Electricity (Wiring) Regulations, owners of electrical installations shall have their installations inspected, tested and certified periodically. Failure to comply with the requirements would present safety hazards resulting in fire or power outage, and the offenders will be prosecuted. For typical residential or commercial premises, electrical installations with an approved loading exceeding 100 amperes shall be inspected, tested and certified at least once every five years. The Periodic Test Certificate (Form WR2) shall be submitted to EMSD for endorsement. It should be noted that electrical work (including inspection, maintenance, repair, etc.) must be carried out by a registered electrical contractor.

With a view to preventing electrical accidents and thus ensuring public safety, EMSD has been taking proactive approaches to promote the importance of PITC to building owners. EMSD makes concerted efforts with property management companies, trade organizations, District Council, Home Affairs Department (District Offices), Buildings Department, etc. to facilitate the PITC works over the territory.

As different buildings may have specific operational needs during PITC works, property management companies and registered electrical contractors can liaise with building owners and tenants to work out a PITC plan before commencement of the works in order to suit their specific needs. For example, they may arrange to suspend and resume the power supply by zones, provide temporary power supply during PITC works, devise a contingency plan to handle emergency situations, etc.

This webpage not only provides useful information for the public and other relevant parties but also gives technical information for the trade. You may contact us if you have any enquiry or require further information in arranging PITC.

Pursuant to Regulation 20 of the “Electricity (Wiring) Regulations”, owners of electrical installations shall have their installations inspected, tested and certified periodically to confirm that the requirements of the Electricity Ordinance have been met. The frequency for such inspection, test & certification may be at least once every 12 months or at least once every 5 years depending on the type of installation. Certification for the above shall be made on specified forms -

From 30 June 2022, the endorsement of Periodic Test Certificate (Form WR2) can be applied online through "EMSD (Regulatory Services) Web Based Registration Services" and "iAM Smart +" by mobile phone or computer. The owners of fixed electrical installations will receive the electronic periodic test certificates by email after the endorsement is completed. Please read the guidelines and requirements for submitting the online application prior to using the services.

Offenders will be prosecuted. Lack of maintenance of electrical installations would also present safety hazards resulting in fire or power outage.

If your fixed electrical installations are located at:

A place of public entertainment (e.g. cinema),

A place of public entertainment (e.g. cinema), Premises for the production or storage of dangerous goods (e.g. DG store), or

Premises for the production or storage of dangerous goods (e.g. DG store), or Premises with a high voltage fixed electrical installation (exceeding 1000V root mean square alternating current between conductors),

Premises with a high voltage fixed electrical installation (exceeding 1000V root mean square alternating current between conductors),By law, the electrical installations shall be inspected, tested and certified at least once every 12 months.

If your fixed electrical installations are located at:

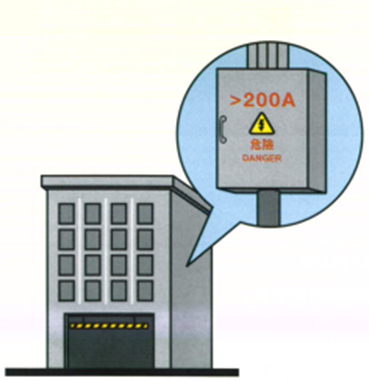

A factory with an approved loading exceeding 200A, or

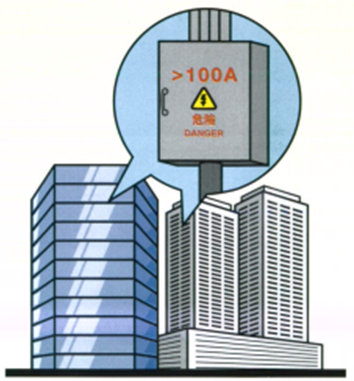

A factory with an approved loading exceeding 200A, or Premises including commercial or residential unit and building with an approved loading exceeding 100A,

Premises including commercial or residential unit and building with an approved loading exceeding 100A,By law, the electrical installations shall be inspected, tested and certified at least once every 5 years.

The approved loading of the communal electrical installation in most buildings exceeds 100A, whereas that of the electrical installation in general residential units usually does not exceed. If in doubt, the owners may arrange a registered electrical contractor to check.

The approved loading of the communal electrical installation in most buildings exceeds 100A, whereas that of the electrical installation in general residential units usually does not exceed. If in doubt, the owners may arrange a registered electrical contractor to check. Check if your "Periodic Test Certificate – Form WR2" is still valid. If the certificate will soon expire, please arrange your electrical installations to be inspected, tested and certified again immediately.

Check if your "Periodic Test Certificate – Form WR2" is still valid. If the certificate will soon expire, please arrange your electrical installations to be inspected, tested and certified again immediately. Live work can easily cause accidents which may result in death and injury and the loss of property. In the event of the electrical installation being damaged in the accident, prolonged power outage may result. In this connection, the Code of Practice for the Electricity (Wiring) Regulations requires that registered electrical contractors must arrange for the suspension of power supply to the electrical circuits concerned before electrical work can commence on the circuits.

Live work can easily cause accidents which may result in death and injury and the loss of property. In the event of the electrical installation being damaged in the accident, prolonged power outage may result. In this connection, the Code of Practice for the Electricity (Wiring) Regulations requires that registered electrical contractors must arrange for the suspension of power supply to the electrical circuits concerned before electrical work can commence on the circuits. In carrying out any electrical work for the building, such as addition, alteration, maintenance and inspection, building owners, owners’ corporations or property management companies should collaborate with electricity suppliers and/or registered electrical contractors to arrange power suspension with sufficient time for workers to carry out the electrical work. The electricity supplier and/or registered electrical contractor should also liaise closely with building owners, owners’ corporations or property management companies to put in place power suspension arrangements and temporary measures which can match the operational needs of the building, so as to minimise the impact of the electrical work to the building users.

In carrying out any electrical work for the building, such as addition, alteration, maintenance and inspection, building owners, owners’ corporations or property management companies should collaborate with electricity suppliers and/or registered electrical contractors to arrange power suspension with sufficient time for workers to carry out the electrical work. The electricity supplier and/or registered electrical contractor should also liaise closely with building owners, owners’ corporations or property management companies to put in place power suspension arrangements and temporary measures which can match the operational needs of the building, so as to minimise the impact of the electrical work to the building users.The communal electrical installations of a building to be inspected and tested periodically normally include the main switch, riser, secondary meters and switches of all floors, earthing arrangements, equipotential bonding etc. of the power supply system. For buildings, housing estates and clubs completed recently, communal fixed electrical installations may include main switchboards, emergency generators, lifts, fire service installations, pump installations, lightning protection installations and the supply system of security equipment.

To ensure the electrical work is carried out in a safe environment, the upstream switch or circuit breaker must be switched off and isolated before the electrical work is carried out. If the switch or circuit breaker is equipped with a locking mechanism, lock off the circuit breaker or switch, and display securely an appropriate warning notice to prevent accidents caused by the switch or circuit breaker being inadvertently turned on during the electrical work.

Furthermore, for the safety of the electrical workers, RECs should cut off the power company’s electricity supply before carrying out periodic inspection and testing for the main switchboard, and ensure that the electrical work is carried out after the electrical installations are isolated. In submitting periodic test certification for endorsement, the power company’s record for power suspension shall also be submitted for vetting.

Before the test, registered electrical contractors and workers should make proper preparations and arrange power suspension with sufficient time to carry out the electrical work. In particular, discussions with owners of fixed electrical installations are vital. Work programmes should be drawn up and cover the following matters:

Precautionary measures should be taken by registered electrical workers responsible for the work during inspection and testing and the method of tests should be such that no danger to persons or property can occur even if the circuit being tested is defective. Moreover, the responsible registered electrical workers should conduct inspection and testing in person or monitor the inspection and testing on the spot to ensure electrical safety.

In the event of any inspection or test indicating failure to comply, that test and those preceding, the results of which may have been influenced by the fault indicated, should be repeated after the fault has been rectified to ensure safety.

| Requirements | Schedule of test results / checklists to be used |

|---|---|

| Inspection and testing for electrical installation | Schedule of Test Results for Electrical Wiring (Sample) [PDF format (70KB)] |

| Periodic inspection and testing for a low voltage installation | Checklist 1 [PDF format (1.14MB)] |

| Items for testing for Renewable Energy Power System Installations | Checklist 3 [PDF format (654KB)] |

| Inspection and testing for a high voltage installation | Checklist 5 [PDF format (657KB)] |

Guideline for Periodic Inspection, Testing and Certification (PITC) Work

Common Mistakes - (1) Dates |

|

| The main inspection and test date (1A) | |

|---|---|

| Common Mistakes | Points to Note |

| 1. Leave the space blank. | Should fill in the inspection and test date correctly. |

| 2. Make mistakes when filling in the dates. |

|

| The date of signature by the REW (1B) and the date of signature by the registered electrical contractor (REC) / owner of the fixed electrical installation (1C) | |

| Common Mistakes | Points to Note |

| 1. Leave the space blank. | Should fill in the date of signature correctly. |

| 2. The date (1C) is earlier than (1B) or (1A), the date (1B) is earlier than (1A), or the date (1A), (1B) or (1C) is later than the date of the endorsement application. |

|

Common Mistakes - (2) Choosing the Box / Signature |

|

| Whether an additional form WR2A is attached (2A) | |

|---|---|

| Common Mistakes | Points to Note |

| 1. Leave the space blank. | Should choose the correct box. |

| 2. Choose the wrong box. | If the upper box is chosen, that means there is no additional form WR2A. If the lower box is chosen, that means an additional form WR2A is attached. The upper and lower boxes shall not be chosen at the same time. |

| The identity of the signer (2B) | |

| Common Mistakes | Points to Note |

| 1. Leave the space blank. | Should choose the correct box. |

| 2. Choose the wrong box. |

|

| Signature of the REW (2C) | |

| Common Mistakes | Points to Note |

| 1. Leave the space blank. | Should sign correctly. |

| 2. A photocopied signature is given. | Should sign in one's own handwriting. |

| Signature of the REC / the owner of the fixed electrical installation (2D) | |

| Common Mistakes | Points to Note |

| 1. Leave the space blank. | Should sign correctly. |

| 2. A photocopied signature is given. | Should sign in one's own handwriting. |

| 3. Signed by a person not authorised by the REC |

|

Common Mistakes - (3) Type of premises |

|

| Type of premises where the fixed electrical installation is located (3) | |

|---|---|

| Common Mistakes | Points to Note |

| 1. Leave the space blank. | Should be filled in correctly. |

| 2. Provide wrong information. | Should be filled in according to the type of premises where the electrical installation is located, for example cinema, factory and industrial undertakings, residential unit, restaurant, karaoke, home for the elderly, hotel, hospital, etc. |

Common Mistakes - (4) Address of the electrical installation |

|

| Address of the fixed electrical installation (4) | |

|---|---|

| Common Mistakes | Points to Note |

| 1. Leave the space blank, provide wrong information, fail to give full information (e.g. omit the street number), etc. |

|

| 2. The address of the installation shown on the form is different from the address shown on the wiring diagram. | Make sure the information is correct before submitting the Periodic Test Certificate. |

Common Mistakes - (5) Information on the owner of the electrical installation |

|

| Name of the owner of the fixed electrical installation (5A) | |

|---|---|

| Common Mistakes | Points to Note |

| 1. Leave the space blank, provide wrong information, fail to give full information (e.g. wrongly fill in the name of the REC), especially when the applicant intends that the endorsed Periodic Test Certificate will be returned to the owner of the installation by mail. |

|

| Correspondence address of the owner of the fixed electrical installation (5B) | |

| Common Mistakes | Points to Note |

| 1. Leave the space blank, provide wrong information, fail to give full information (e.g. wrongly fill in the address of the REC). |

|

| Contact telephone number of the owner of the fixed electrical installation (5C) | |

| Common Mistakes | Points to Note |

| 1. Wrongly filled in the contact telephone number of the REW or the REC. | Should only fill in the contact telephone number of the owner of the installation. |

Common Mistakes - (6) The inspected part of the electrical installation |

|

| Description of the inspected part of the fixed electrical installation (6) | |

|---|---|

| Common Mistakes | Points to Note |

| 1. Omission, fail to give full information. | Should be filled in correctly. |

| 2. Parts of the electrical installation are not inspected, but the "excluded" parts are not mentioned. |

|

3 Kai Shing Street, Kowloon, Hong Kong

(Operating hours: 9:00 a.m. - 5:15 p.m. on Monday to Friday; closed on Saturday, Sunday and public holiday)

info@emsd.gov.hk

1823

2895 4929