Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD delivered the opening remarks.

Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD delivered the opening remarks.

The EMSD has been committed to enhancing the technical standards and safety awareness of the electrical trade in collaboration with trade associations. Since 2001, the EMSD has co-organised the technical seminar every year with the Hong Kong and Kowloon Electrical Engineering & Appliances Trade Workers Union (Trade Workers Union) and the Hong Kong Electrical Contractors’ Association (Contractors’ Association).

With the theme of encouraging the trade to take sufficient preventive measures to avoid incidents and safeguard public well-being, the seminar of year 2022 was held on 22 November 2022 at the EMSD Headquarters. In view of the epidemic, the seminar was conducted mainly via webcasting, but a limited number of seats were provided in the venue for registered electrical workers (REWs) to attend the seminar on site. The seminar attracted nearly 1 000 viewers, a record high for the event.

The seminar was kicked off by Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD. In his opening remarks, Mr Poon said that the latest edition of the Code of Practice for the Electricity (Wiring) Regulations (CoP) came into effect in December 2021, and REWs should understand and comply with the CoP for safety sake. If the trade follows the CoP and pay attention to electricity safety at work, electrical incidents can be avoided.

The seminar was divided into two parts. In the first half of the seminar, Ir Dr F C Chan, representative of the Contractors’ Association, briefed the participants on electricity safety and the responsibilities of a registered electrical contractor/ worker, while Mr M C Chong, Electrical and Mechanical Engineer of the EMSD, explained the analysis on incidents related to electrical work and suggested solutions. In the second half of the seminar, Mr Ricky Tsang, Senior Consultant of the Occupational Safety and Health Council, introduced the Lockout and Tagout procedures and requirements, and shared experience from electrical accidents.

Group photo of Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD (seventh right),

Group photo of Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD (seventh right),

Mr Lok Kwei-sang, Chairman of the Workers Union (eighth left),

Mr Choi Kan-man, Chairman of the Contractors' Association (sixth right) and other officiating guests.

Ir Dr F C Chan, representative of the Contractors Association briefed the participants on electricity safety and the responsibilities of a registered electrical contractor or worker.

Ir Dr F C Chan, representative of the Contractors Association briefed the participants on electricity safety and the responsibilities of a registered electrical contractor or worker.

In 2022, the EMSD also resumed the organisation of the Outstanding Registered Electrical Worker Awards Scheme in collaboration with the Trade Workers Union and the Contractors' Association. The scheme is aimed at promoting a work safety culture among the trade by encouraging REWs to improve quality control and work processes, enhancing technical standards and setting examples for the trade. The winners of the Outstanding Registered Electrical Worker Awards 2022 have been elected. They well deserve the awards, as exemplified by their high professionalism and great attention to safety at work displayed in the practical test. To commend the awardees for their outstanding performance, an award presentation ceremony was especially arranged during the seminar.

With the relaxation of social distancing measures, "The Outstanding Registered Electrical Contractors Competition 2023" and "The Annual Technical Seminar 2023" (in physical mode) are scheduled in June and September 2023 respectively. Details will be announced in the relevant Departmental website.

Mr Chu Kei-ming, Assistant Director of the EMSD, presented souvenirs to the representatives of two nominating organisations, Hongkong Electric Company, Limited and REC Engineering Company Limited.

Mr Chu Kei-ming, Assistant Director of the EMSD, presented souvenirs to the representatives of two nominating organisations, Hongkong Electric Company, Limited and REC Engineering Company Limited.

Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD and Mr Kwan Sun-chuen, Chairman of the adjudicating panel for the Outstanding Registered Electrical Worker Awards presented the awards to the winners.

Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD and Mr Kwan Sun-chuen, Chairman of the adjudicating panel for the Outstanding Registered Electrical Worker Awards presented the awards to the winners.

[PDF format (6.71MB)]

[PDF format (6.71MB)] Artiste Odilia

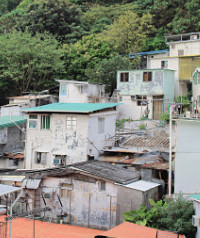

Artiste Odilia After years of weathering of the earthing systems, earthing conductors of fixed electrical installations in village premises may have problems such as rusting, intermittent connection, loose contact, mechanical damages and breaks, resulting in poor earthing, and hence failure to meet the safety requirements of effective earthing and provide effective protection.

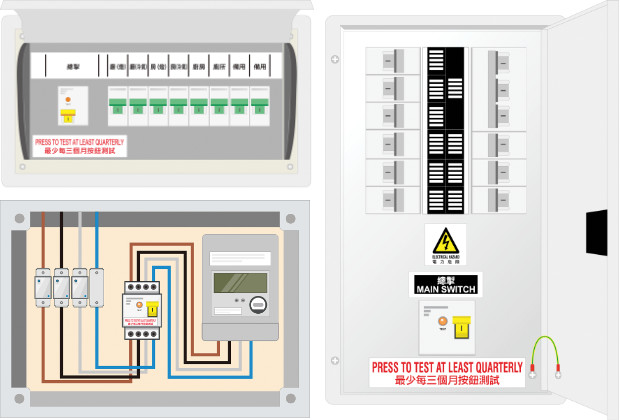

After years of weathering of the earthing systems, earthing conductors of fixed electrical installations in village premises may have problems such as rusting, intermittent connection, loose contact, mechanical damages and breaks, resulting in poor earthing, and hence failure to meet the safety requirements of effective earthing and provide effective protection. To prevent such incidents, fixed electrical installations in village premises in the New Territories are required to be installed with RCDs for further protection, in order that automatic disconnection of earth fault current can be achieved even when the earthing is poor. As required by Code 11J of the Code of Practice for the Electricity (Wiring) Regulations, protection by means of an RCD should be provided for fixed electrical installations supplied from overhead line system and fixed electrical installations in premises under the “List of Recognised Villages under the New Territories Small House Policy”. Simply put, owners of premises can meet the relevant requirements by installing a main switch incorporated with an RCD upstream to the electric meter or in the distribution board.

To prevent such incidents, fixed electrical installations in village premises in the New Territories are required to be installed with RCDs for further protection, in order that automatic disconnection of earth fault current can be achieved even when the earthing is poor. As required by Code 11J of the Code of Practice for the Electricity (Wiring) Regulations, protection by means of an RCD should be provided for fixed electrical installations supplied from overhead line system and fixed electrical installations in premises under the “List of Recognised Villages under the New Territories Small House Policy”. Simply put, owners of premises can meet the relevant requirements by installing a main switch incorporated with an RCD upstream to the electric meter or in the distribution board.

RCD tester

RCD tester Test adapter for

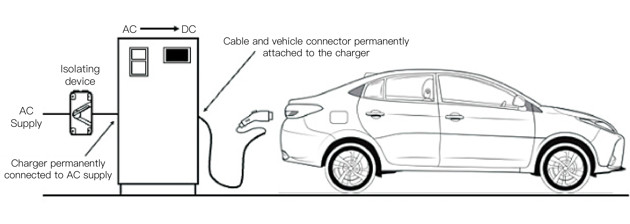

Test adapter for  Typical arrangement of a DC EV charging facility for Mode 4 charging

Typical arrangement of a DC EV charging facility for Mode 4 charging

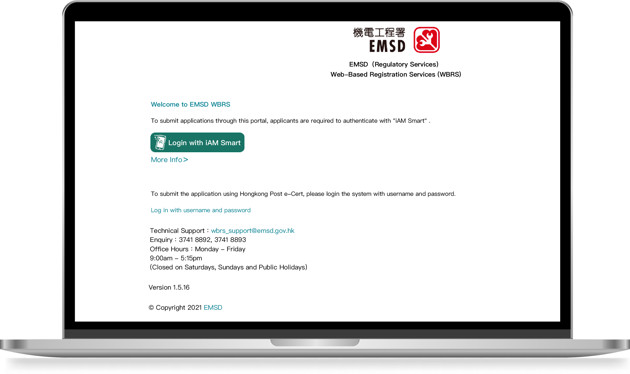

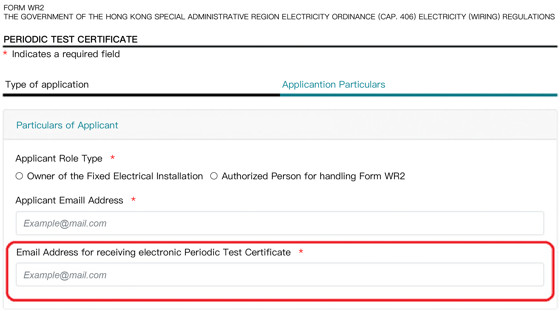

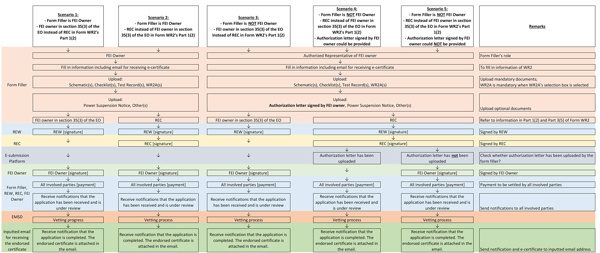

![QR code to download the Flow Chart for the detailed online application process for endorsement of periodic test certificates [Excel format]. QR code to download the Flow Chart for the detailed online application process for endorsement of periodic test certificates [Excel format].](/filemanager/en/content_1507/e12-en.png) Flow Chart:

Flow Chart:

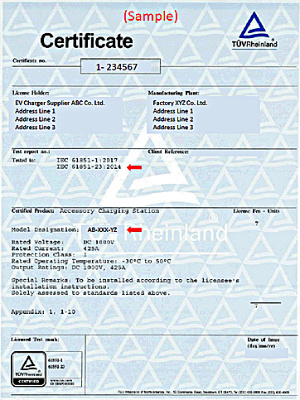

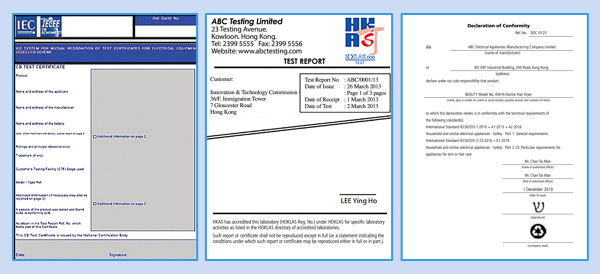

Samples of the Certificates of Safety Compliance

Samples of the Certificates of Safety Compliance

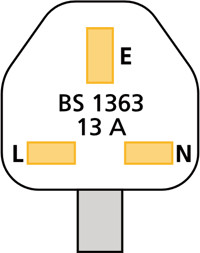

Plug of a refrigerator

Plug of a refrigerator To know more about electrical products safety, please click the link or scan the QR code to visit the

To know more about electrical products safety, please click the link or scan the QR code to visit the

Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD delivered the opening remarks.

Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD delivered the opening remarks. Group photo of Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD (seventh right),

Group photo of Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD (seventh right),

Ir Dr F C Chan, representative of the Contractors Association briefed the participants on electricity safety and the responsibilities of a registered electrical contractor or worker.

Ir Dr F C Chan, representative of the Contractors Association briefed the participants on electricity safety and the responsibilities of a registered electrical contractor or worker.

Mr Chong Man-chun, Electrical and Mechanical Engineer of the EMSD explained the analysis on incidents related to electrical work and suggested solutions.

Mr Chong Man-chun, Electrical and Mechanical Engineer of the EMSD explained the analysis on incidents related to electrical work and suggested solutions. Mr Ricky Tsang, Senior Consultant of the Occupational Safety and Health Council introduced the Lockout and Tagout procedures and requirements, and shared experience from electrical accidents.

Mr Ricky Tsang, Senior Consultant of the Occupational Safety and Health Council introduced the Lockout and Tagout procedures and requirements, and shared experience from electrical accidents. Mr Chu Kei-ming, Assistant Director of the EMSD, presented souvenirs to the representatives of two nominating organisations, Hongkong Electric Company, Limited and REC Engineering Company Limited.

Mr Chu Kei-ming, Assistant Director of the EMSD, presented souvenirs to the representatives of two nominating organisations, Hongkong Electric Company, Limited and REC Engineering Company Limited. Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD and Mr Kwan Sun-chuen, Chairman of the adjudicating panel for the Outstanding Registered Electrical Worker Awards presented the awards to the winners.

Mr Poon Kwok-ying, Deputy Director/Regulatory Services of the EMSD and Mr Kwan Sun-chuen, Chairman of the adjudicating panel for the Outstanding Registered Electrical Worker Awards presented the awards to the winners.